- Home

- >

- News

- >

- Industry news

- >

News

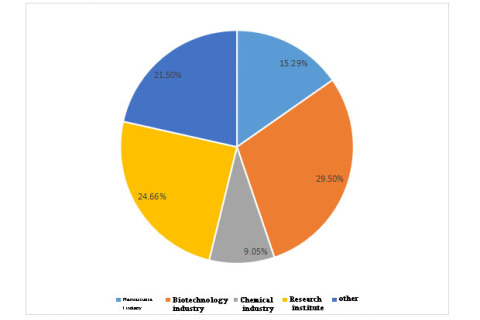

Global X-ray diffractometer (XRD) has developed steadily in recent years, and China is a market with great development prospects.

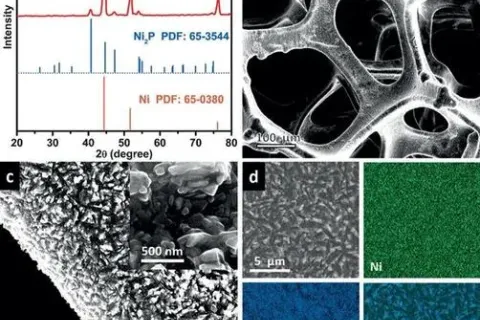

Taking deposition scaling as an example, this paper introduces how to use X-ray diffractometer for qualitative phase and quantitative analysis.

The application of new technologies and new products such as 5G, big data, and artificial intelligence will bring a huge semiconductor market demand, and global semiconductor equipment spending has entered an upward cycle.

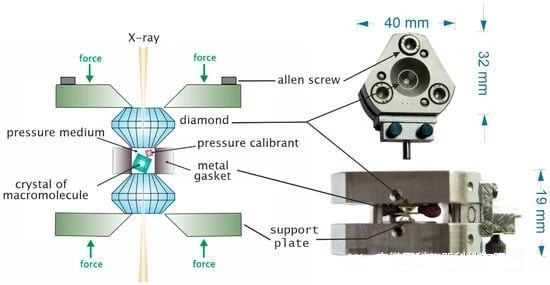

In recent years, there has been a growing interest in the measurement of high-pressure biological samples. This is reflected in the development of new techniques for pressure measurement that are different from those implemented by DAC. One of them is the technique of freezing crystals under pressure.

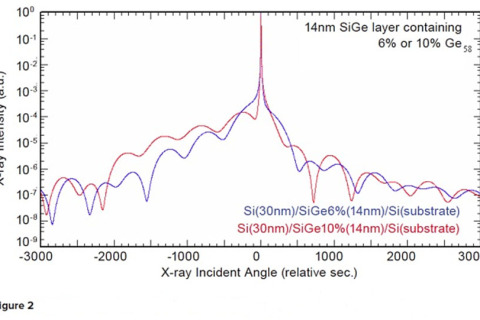

High-resolution XRD (HR-XRD) is a common method for measuring the composition and thickness of compound semiconductors such as SiGe, AlGaAs, InGaAs, etc.

X-ray diffractometer (XRD) can be divided into X-ray powder diffractometer and X-ray single crystal diffractometer, the basic physical principle of the two is the same.

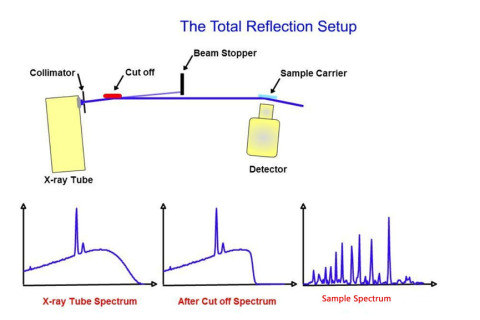

Total reflection X-ray fluorescence (TXRF) is a surface element analysis technique commonly used to analyze particles, residues, and impurities on smooth surfaces.

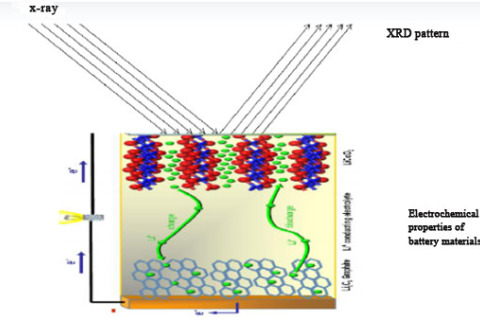

XRD is a means of research which is Diffraction by X-Ray diffraction of a material to analyze its diffraction pattern to obtain information such as the composition of the material, the structure or shape of atoms or molecules inside the material.

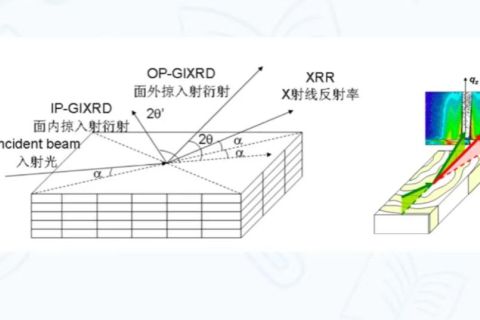

Grazing-incidence X-ray diffraction (GI-XRD) is a kind of X-ray diffraction technique, which is different from the traditional XRD experiment, mainly by changing the Angle of X-ray incidence and the orientation of the sample.

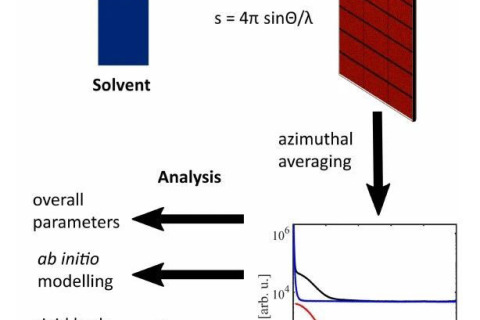

In recent years, X-ray small Angle scattering technique of biological macromolecules has been widely paid attention to. This article will mainly introduce the relevant progress of the combination of biological small Angle and other techniques in recent years.

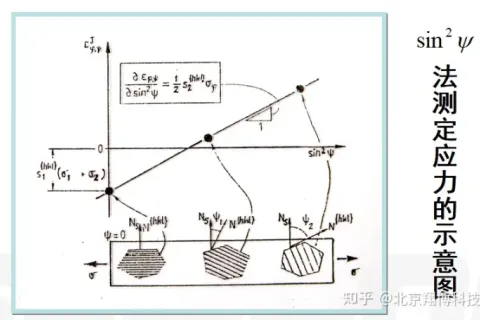

It is necessary to reduce the harmful residual stress and predict the distribution trend and value of residual stress. In this paper, the non-destructive testing method of residual stress testing is introduced.

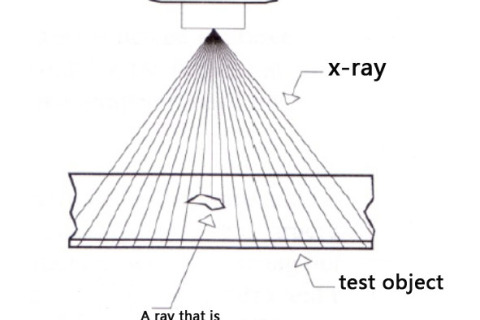

Nondestructive testing is based on the development of modern science and technology. With the development of modern industry, the application of non-destructive testing is more and more popular.