News

The WBK-01 X-ray irradiator generates high-energy X-rays to irradiate cells or small animals. X-ray irradiator is used for various basic and applied research. Throughout history, radioactive isotope irradiators have been used, which require transporting samples to a core irradiation facility. Today, smaller, safer, simpler, and lower cost X-ray irradiator can be installed in laboratories for convenient and rapid irradiation of cells. Various samples can be directly irradiated in the laboratory without affecting fertility or safety. The X-ray irradiator is easy to use for personnel without professional X-ray training, and there are no expensive license applications or safety or radiation source maintenance costs. This device is easy to operate, safe, reliable, and cost-effective, and can replace radioactive isotope sources. 1. Principle of X-ray irradiator: The X-ray tube in the X-ray irradiator generates high-energy electrons, which produce X-rays when they collide with the target material (usually tungsten). Accelerating electrons through a high-voltage electric field to obtain sufficient energy to generate the required X-ray wavelength and intensity. Then, the X-rays are adjusted and optimized through a series of collimators, filters, and other devices, and finally irradiated onto the sample. The main components of an X-ray irradiator are: The X-ray irradiator mainly includes X-ray tubes, high-voltage generators, control circuits, cooling systems, safety protection devices, and sample rooms. Among them, the X-ray tube is the core component responsible for generating X-rays; The high-voltage generator provides the required high voltage and current for the X-ray tube; The control circuit is used to control parameters such as the generation, intensity, and irradiation time of X-rays; The cooling system ensures that the equipment will not be damaged due to overheating during operation; The safety protection device ensures the safety of operators and the usage environment. 3. Application areas of X-ray irradiator: The X-ray irradiator can be used in the field of biology: it can be used for cell culture and division inhibition research, gene change induction, stem cell research, small animal irradiation, T-B cell research, blood cell research, bone marrow transplantation irradiation, transplantation immunity, immunosuppressive therapy, radiation sensitivity research, DNA damage research, etc. The X-ray irradiator can be used in the medical field: in tumor treatment, it can be used to locally irradiate the tumor site, kill cancer cells or inhibit their growth; The X-ray irradiator can also be used as an auxiliary diagnosis for certain diseases, such as helping to determine the condition by observing the imaging changes of tissues and organs through X-rays. The X-ray irradiator can be used in the food industry: it can be used for food irradiation preservation, killing microorganisms in food through X-ray irradiation, inhibiting enzyme activity, thereby extending the shelf life of food while maintaining its original taste and nutritional content. The X-ray irradiator can be used in the industrial field: it can be used for material performance testing and modification, such as cross-linking treatment of polymer materials to improve their strength and stability; It can also be used for non-destructive testing to detect defects and cracks inside materials. In summary, X-ray irradiator is an important scientific and industrial device with broad application prospects and value.

The X-ray crystal orienter is an indispensable instrument for precision machining and manufacturing of crystal devices. X-ray crystal orienter utilizes the principle of X-ray diffraction to accurately and quickly determine the cutting angle of natural and artificial single crystals (piezoelectric crystals, optical crystals, laser crystals, semiconductor crystals), and is equipped with a cutting machine for directional cutting of the above-mentioned crystals. The X-ray crystal orienter is widely used in the research, processing, and manufacturing industries of crystal materials. 1. Principle of X-ray crystal orienter: The X-ray crystal orienter utilizes the principle of X-ray diffraction to accurately and quickly determine the cutting angle of natural and artificial single crystals (piezoelectric crystals, optical crystals, laser crystals, semiconductor crystals). Equipped with a cutting machine, X-ray crystal orienter can be used for directional cutting of the above-mentioned crystals and is an indispensable instrument for precision machining and manufacturing of crystal devices. The X-ray crystal orientation instrument has a measurement accuracy of ± 30 inches, with a digital display mode and a smaller reading of 10 inches. Can measure samples with a diameter of 1-30 kilograms and 2-8 inches. Angle display: digital mode, measurement accuracy ± 30 inches. 2. Characteristics of X-ray crystal orienter: Easy to operate, no need for professional knowledge or proficient skills. The digital display angle is easy to observe and reduces reading errors. The monitor can be zeroed at any position for easy display of chip angle deviation values. The dual angle measuring instrument can work simultaneously, improving efficiency. The X-ray crystal orienter has a special integrator with peak amplification, which improves the detection accuracy. The integration of X-ray tube and high-voltage cable increases high-voltage reliability. The detector high-voltage adopts DC high-voltage module and vacuum suction sample board, which improves the angle measurement accuracy and speed. The main components of an X-ray crystal orienter are: Radiation tube: Typically, a copper target is used as the anode and grounded, while forced air cooling is employed for cooling. High voltage power supply: provides stable high voltage and current for X-ray tubes, and is one of the core components of the entire system. Detector: used to receive diffracted X-ray photons and convert them into electrical signals for subsequent processing and analysis. Goniometer: used to accurately measure the rotation angle of crystal samples, thereby determining the orientation information of the diffraction plane. Data processing system: processes, analyzes, and stores the signals output by the detector to obtain information about the crystal structure. 4. Application areas of X-ray crystal orienter: Materials Science: Used to study the crystal structures of various materials, including metals, ceramics, semiconductors, etc. Geology: Used for identifying mineral types, analyzing rock structures, etc. Chemistry: used to study the structure and changes of molecular crystals. Physics: used to explore the microstructure and physical properties of matter. In summary, with the continuous progress and innovation of science and technology,X-ray crystal orienter is believed that there will be more new materials and technologies applied in various fields in the future, promoting the continuous development of human society.

The TDF series X-ray crystal analyzer is a large-scale analytical instrument used to study the internal microstructure of substances. The X-ray crystal analyzer is mainly used for single crystal orientation, defect inspection, determination of lattice parameters, determination of residual stresses, study of the structure of plates and rods, study of the structure of unknown substances, and single crystal dislocations. A X-ray crystal analyzer is a precision instrument that uses the principle of X-ray diffraction to analyze and determine the internal structure and composition of substances. 1. The working principle of X-ray crystal analyzer: The X-ray crystal analyzer is based on Bragg's law, which states that when X-rays are irradiated onto a crystal, diffraction occurs at a specific angle, forming diffraction spots or peaks. By measuring the angles and intensities of these diffractions, the internal structure and composition of the crystal can be inferred. 2. Components of X-ray crystal analyzer: (1) X-ray source of X-ray crystal analyzer: a device that generates X-rays, usually an X-ray tube, consisting of a filament, a target material, and a high-voltage power supply. X-ray tube of X ray crystal analyzer: Rated power: 2.4KW; Focus size (mm2): Point focus (1 × 1) Line focus (1 × 10); Target materials: Cu, Co, Fe, Cr, Mo, W, etc. High voltage generator of X-ray crystal analyzer (controlled by imported PLC): Tube voltage: 10-60KV; Tube current: 2-60mA; Stability of tube voltage and tube current ≤ ± 0.005%; Rated output power: 3KW. High voltage cable for X ray crystal analyzer: Dielectric voltage ≥ 100KV; Length: 2M. (2) The spectral crystal of X ray crystal analyzer: used to separate X-rays of different wavelengths, the X-ray crystal analyzer is a key component for achieving spectral separation. (3) Detector of X-ray crystal analyzer: used to detect X-rays scattered by the sample and convert them into electrical signals for subsequent processing. (4) Angle measuring instrument of X-ray crystal analyzer: an instrument used for precise measurement of diffraction angle, which is one of the important components to ensure measurement accuracy. (5) The control and data processing system of X-ray crystal analyzer: used to control the entire analysis process, process and analyze the collected data. Modern instruments are usually equipped with computer software to simplify the data analysis process. 3. Characteristics of X-ray crystal analyzer: The TDF series X ray crystal analyzer adopts a vertical tube sleeve, and four windows can be used simultaneously. The TDF series X-ray crystal analyzer adopts imported PLC control technology, with high control accuracy and good anti-interference performance, which can achieve reliable operation of the system. The PLC controls the high-voltage switch, lifting, and has the function of automatically training the X-ray tube, effectively extending the service life of the X-ray tube and instrument. 4. Application areas of X-ray crystal analyzer Materials Science: Research the crystal structure, phase transition, defects, etc. of materials to provide important support for the development of new materials. Chemistry: involving crystal chemistry, medicinal chemistry, etc., can be used to analyze compound structures, study chemical reaction mechanisms, etc. Biology: Used for structural analysis of biomolecules, drug design and screening, etc., the X-ray crystal analyzer is of great significance for understanding life processes and disease mechanisms. Environmental science plays an important role in the development of catalysts, characterization of nanomaterials, and analysis of pollutants. Geology:Mineral identification, rock genesis research, geochronology and other fields of study also rely on X-ray crystal analyzers. The X-ray crystal analyzer is a powerful and widely used analytical instrument that plays an irreplaceable role in multiple fields. With the continuous advancement of technology and the continuous development of the market, its performance and application scope will be further improved and expanded.

The TDM-10 desktop x ray diffraction instrumentation is an instrument used for analyzing the phase structure of materials, which can be equipped with scintillation/proportional/linear array detectors. 1. The working principle of TDM-10 desktop x ray diffraction instrumentation:Based on Bragg's law, when a monochromatic X-ray beam is incident on a crystal, if the Bragg diffraction condition is satisfied (n λ=2dsin θ, where λ is the wavelength of the X-ray, d is the interplanar spacing, and θ is the incident angle), atoms or molecules in the crystal will scatter and interfere with the X-ray, forming a specific diffraction pattern. By measuring the diffraction intensity at different angles, the structural information of the crystal can be obtained. 2. Characteristics of TDM-10 desktop x ray diffraction instrumentation: The high resolution of a desktop x ray diffraction instrumentation enables precise measurement of the crystal structure of substances, which is crucial for studying complex mixtures or searching for low content polycrystalline and trace phases. Non destructive analysis of desktop x ray diffraction instrumentation: During the testing process, it will not cause damage to the sample, and the sample can remain in its original state for further testing or use. The operation of desktop X-ray powder diffraction equipment is simple: Modern desktop X-ray powder diffraction equipment usually have automation and intelligence functions, making the operation more convenient and reducing the requirements for the operator's professional knowledge and skills. The versatility of desktop X-ray powder diffraction equipment: X-ray powder diffraction equipment can perform various analyses such as phase qualitative and quantitative analysis, lattice constant analysis, stress analysis, etc. 3. Technical parameters of TDM-10 desktop X-ray powder diffraction equipment: Desktop x ray diffraction machine has a small volume; High frequency and high voltage power supply reduces the overall power consumption of the machine; Can quickly calibrate and test samples; Simple circuit control, easy to debug and install; The measurement accuracy of diffraction peak position is 0.001 °; Detector: scintillation, proportional, linear array; Range of 2 θ:- 10°~150° Power: 600W; Maximum voltage: 40kV; Maximum current: 15mA; X-ray tubes: corrugated ceramic tubes, metal ceramic tubes, glass tubes. 4. Application areas of TDM-10 desktop x ray diffraction machine: Materials Science: Used to study the crystal structure, phase composition, grain size, crystallinity, etc. of metals, ceramics, semiconductors, and other materials, helping materials scientists understand the properties and characteristics of materials. In the field of chemistry, x ray diffraction machine can be used in the manufacturing industry of catalysts, cement, pharmaceuticals, and other products to identify phases in unknown samples, as well as to quantitatively analyze known phases in mixed samples. Geology: Conducting phase analysis on ores, rocks, etc. to determine their mineral composition and structure. Environmental science: used to analyze the mineral composition and pollutant forms in environmental samples such as soil and sediment. Food industry: detecting crystal components, additives, etc. in food. The TDM-10 desktop x ray diffraction machine is a powerful analytical instrument with important application value in multiple fields.

The TDM-20 high-power X-ray diffractometer(Benchtop XRD)is mainly used for phase analysis of powders, solids, and similar paste materials. The principle of X-ray diffraction can be used for qualitative or quantitative analysis, crystal structure analysis, and other polycrystalline materials such as powder samples and metal samples. Benchtop XRD is widely used in industries such as industry, agriculture, national defense, pharmaceuticals, minerals, food safety, petroleum, education, and scientific research. 1、Core features of TDM-20 benchtop X-ray diffractometer(Benchtop XRD): The loading of the new high-performance array detector has greatly improved the overall performance of the device, with a small size and light weight; The whole machine is integrated into the desktop size (usually ≤ 1m³), saving space and suitable for small laboratories or teaching environments;The working power of high-frequency and high-voltage power supply can reach 1600W; Quick analysis, able to calibrate and test samples quickly; By using high-performance detectors (such as two-dimensional detectors) and optimizing the optical path, sample scanning can be completed in a few minutes; Simple circuit control, easy to debug and install; The angle repeatability can reach 0.0001; Low power consumption and safety, using low-power X-ray tubes (such as ≤ 50W), equipped with multiple radiation protection, no need for special shielding rooms; User friendly, equipped with automation software, supporting one click operation, real-time data visualization, and standard database (such as ICDD PDF) comparison. 2. Typical application scenarios of TDM-20 benchtop X-ray diffractometer(Benchtop XRD): Materials Science of X-ray diffractometer(Benchtop XRD): Rapid identification of crystal structure and phase composition (such as metals, ceramics, polymers). Materials Science of X-ray diffractometer(Benchtop XRD): Industrial site testing of the crystal purity of raw materials or finished products (such as pharmaceuticals and battery materials). Materials Science of X-ray diffractometer(Benchtop XRD): Undergraduate experimental teaching, visually demonstrating the Bragg diffraction principle. Materials Science of X-ray diffractometer(Benchtop XRD): Mineral composition analysis of cultural relics or preliminary screening of field samples. 3.Technical parameters of TDM-20 benchtop X-ray diffractometer(Benchtop XRD): Project : parameter range X-ray source:Cu target (λ=1.54 Å), Mo target optional Voltage/current:10-50 kV/0.1-2 mA Angle measuring instrument range:0-90 ° 2θ (some models can be extended) Angle resolution:≤ 0.01 ° Detector type: one-dimensional linear or two-dimensional surface detector Sample size: Powder (milligrams), film or block 4.Advantages and limitations of TDM-20 benchtop X-ray diffractometer(Benchtop XRD): Advantages: Low cost (about 1/3-1/2 of large XRD), easy maintenance. Support non-destructive analysis and simple sample preparation (such as directly placing powder). limitations: The resolution and sensitivity are slightly lower than high-end devices, and may not be suitable for ultra-fine structural analysis. Extreme condition testing (such as high-temperature/high-pressure in-situ experiments) is usually not feasible.

The TD-3500 X-ray diffractometer is mainly used for phase qualitative and quantitative analysis, crystal structure analysis, material structure analysis, crystal orientation analysis, macroscopic or microscopic stress determination, grain size determination, crystallinity determination, etc. of powder, block or film samples. The TD-3500 X-ray diffractometer produced by Dandong Tongda Technology Co., Ltd. adopts imported Siemens PLC control, which makes the TD-3500 X-ray diffractometer have the characteristics of high accuracy, high precision, good stability, long service life, easy upgrade, easy operation and intelligence, and can flexibly adapt to testing analysis and research in various industries! The TD-3500 X-ray diffractometer adopts an X-ray generator (high-frequency and high-voltage solid-state generator, power frequency generator optional), which has a high degree of automation, extremely low failure rate, strong anti-interference ability, good system stability, and can extend the service life of the whole machine. PLC and computer interface automatically control the opening and closing of the light gate, automatically control the rise and fall of tube pressure and tube flow, and have the function of automatically training X-ray tubes. Real time online monitoring using a touch screen to display instrument status. The TD-3500 X-ray diffractometer adopts advanced recording control unit, PLC control circuit, advanced PLC control technology and true color touch screen to achieve human-computer interaction. The system hardware adopts modular design concept, greatly increasing the anti-interference ability of the system and making it more stable. Due to the use of imported Siemens PLC control circuits with high precision and automation, the system can operate stably for a long time without any faults. The TD-3500 X-ray diffractometer system has the following advantages over the microcontroller circuits used by other companies: Simple circuit control, easy to debug and install; Due to its modular design, the system maintenance is very simple, and users can repair and debug it themselves without the need for manufacturer technicians to be present; Adopting advanced true color touch screen to achieve human-computer interaction, with complete protection functions and very convenient operation, the highly three-dimensional animation design is more humanized, intuitive, and convenient for operators to use and judge fault information, etc; Greatly improving the counting stability of the system, thereby enhancing the overall stability of the entire machine; Due to the strong expansion capability of PLC, it can easily expand various functional accessories without the need to add any additional hardware circuits. Detector of TD-3500 X-ray diffractometer Proportional detector (PC) or scintillation detector (SC). High precision angle measuring instrument for TD-3500 X-ray diffractometer The TD series angle measuring instrument adopts imported high-precision bearing transmission, and the motion control is completed by a high-precision fully closed-loop vector drive servo system. The intelligent drive includes a 32-bit RISC microprocessor and a high-resolution magnetic encoder, which can automatically correct extremely small motion position errors, ensuring high precision and accuracy of measurement results. The angle reproducibility can reach 0.0001 degrees, and smaller step angles can reach 0.0001 degrees. Application areas of TD-3500 X-ray diffractometer: Materials Science: Used to study key information such as crystal structure, phase transition behavior, and texture of materials. Chemical analysis: can be used for qualitative or quantitative analysis of organic, inorganic, polymer compounds and other substances. Geology: helps people understand the formation of mineral deposits, the evolution of the Earth, and more. Biopharmaceuticals: Determine the crystal structure of drugs, optimize drug formulations, and improve drug efficacy. X-ray diffractometer is a powerful analytical tool widely used in multiple fields. By accurately measuring diffraction angle and intensity, it can provide detailed information about the crystal structure and composition of materials.

The TD-3700 high-resolution X-ray diffractometer is a new member of the TD series, equipped with a variety of high-performance detectors such as high-speed one-dimensional array detectors, two-dimensional detectors, SDD detectors, etc. It integrates fast analysis, convenient operation, and user safety. The modular hardware architecture and customized software system achieve a perfect combination, making its failure rate extremely low, anti-interference performance good, and ensuring long-term stable operation of high-voltage power supply. The TD-3700 high-resolution X-ray diffractometer supports not only the conventional diffraction data scanning method, but also the transmission data scanning method. The resolution of transmission mode is much higher than that of diffraction mode, which is suitable for structural analysis and other fields. Diffraction mode has strong diffraction signals and is more suitable for routine phase identification in the laboratory. In addition, in the transmission mode, the powder sample can be in trace amounts, which is suitable for data acquisition in cases where the sample size is relatively small and does not meet the requirements of diffraction method for sample preparation. The array detector fully utilizes mixed photon counting technology, with no noise, fast data acquisition, and more than ten times the speed of scintillation detectors. It has excellent energy resolution and can effectively remove fluorescence effects. Multi channel detectors have faster readout times and achieve better signal-to-noise ratios. A detector control system with electronic gating and external triggering effectively completes system synchronization. The working principle of TD-3700 high-resolution X-ray diffractometer: By utilizing the fluctuation of X-rays, when they are irradiated onto a crystal, atoms or ions in the crystal act as scattering centers, scattering X-rays in all directions. Due to the regularity of atomic arrangement in crystals, these scattered waves interfere with each other and reinforce each other in certain directions, forming diffraction. By measuring the diffraction angle and diffraction intensity, the structural information of the crystal can be obtained. The main features of TD-3700 high-resolution X-ray diffractometer are: (1) Easy to operate, one click collection system; (2) Modular design, plug and play instrument accessories, no need for calibration; (3) Real time online monitoring using touch screen to display instrument status; (4) Electronic lead door interlocking device, dual protection, ensuring user safety; (5) High frequency and high-voltage X-ray generator, with stable and reliable performance; (6) Advanced recording control unit with strong anti-interference ability. The high precision of the TD-3700 high-resolution X-ray diffractometer enables high-precision analysis of the crystal structure of materials, such as precise determination of lattice constants, cell parameters, etc. The angle measurement accuracy can reach ±0.0001°. The high resolution of TD-3700 high-resolution X-ray diffractometer can clearly distinguish adjacent diffraction peaks, accurately analyze diffraction information of different crystal planes for complex crystal structures, and reveal the microstructure characteristics of materials. The non-destructive nature of the TD-3700 high-resolution X-ray diffractometer: it will not cause damage to the sample during the testing process, and the sample can be kept in its original state for multiple tests, which is particularly important for precious or difficult to obtain samples. Rapid analysis of TD-3700 high-resolution X-ray diffractometer: Modern high-resolution X-ray diffractometers have fast detection capabilities and can complete sample testing in a short period of time, improving work efficiency. 3. Application areas of TD-3700 high-resolution X-ray diffractometer: Semiconductor materials: used to detect the crystal quality of semiconductor single crystal materials and epitaxial thin films, analyze lattice mismatch, defects and other information, which helps optimize the performance of semiconductor devices. Superconducting materials: Study the crystal structure and phase transition process of superconducting materials to provide a basis for optimizing superconducting properties. Nanomaterials: Analyzing the grain size, crystal structure, microscopic strain, etc. of nanomaterials helps researchers better understand their properties and applications. Other fields: It is also widely used in research and quality control of metal materials, ceramic materials, polymer materials, biomaterials, and other fields. High resolution X-ray diffractometer is a high-precision, high-resolution, non-destructive, and fast analytical instrument with important application value in many fields.

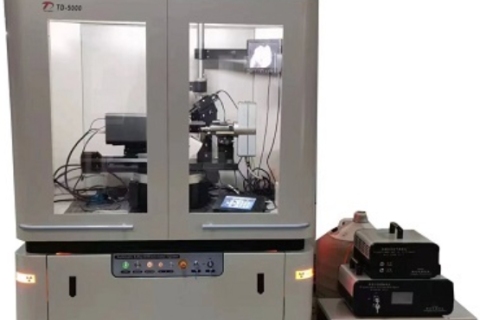

1. Function of single crystal diffractometer: The TD-5000 X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; X-ray single crystal diffractometer can provide information on the crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation.X-ray single crystal diffractometer is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science. The X-ray single crystal diffractometer is a high-tech product funded by the Ministry of Science and Technology of China's National Major Scientific Instrument and Equipment Development Project, led by Dandong Tongda Technology Co., Ltd., filling the gap in the development and production of single crystal diffractometers in China. 2. Characteristics of single crystal diffractometer: The whole machine adopts programmable logic controller (PLC) control technology; Easy to operate, one click collection system; Modular design, plug and play accessories, no need for calibration; Real time online monitoring through touch screen, displaying instrument status; High power X-ray generator with stable and reliable performance; Electronic lead door interlocking device, dual protection. 3. Accuracy of single crystal diffractometer: 2 θ angle repeatability accuracy: 0.0001 °; Minimum step angle: 0.0001 ° Temperature control range: 100K-300K; Control accuracy: ± 0.3K 4. Angle measuring instrument used in single crystal diffractometer: The use of four concentric circles technique ensures that the center of the angle measuring instrument remains unchanged regardless of any rotation, achieving the goal of obtaining the most accurate data and obtaining higher completeness. Four concentric circles are a necessary condition for conventional single crystal diffractometer scanning. 5. High speed two-dimensional detector used in X-ray single crystal diffractometer: The detector combines the key technologies of single photon counting and mixed pixel technology to achieve the best data quality while ensuring low power consumption and low cooling. It is applied in various fields such as synchrotron radiation and conventional laboratory light sources, effectively eliminating the interference of readout noise and dark current. The mixed pixel technology can directly detect X-rays, make the signal easier to distinguish, and efficiently provide high-quality data. 6. Low temperature equipment used in X-ray single crystal diffractometer: The data collected through low-temperature equipment yields more ideal results. With the help of low-temperature equipment, more advantageous conditions can be provided to enable undesirable crystals to obtain ideal results, as well as ideal crystals to obtain more ideal results. Temperature control range: 100K~300K; Control accuracy: ± 0.3K; Liquid nitrogen consumption: 1.1~2 liters/hour; 7. Optional accessory, multi-layer film focusing lens: X-ray tube power: 30W or 50W, etc; Divergence: 0.5~1 mrad; X-ray tube target material: Mo/Cu target; Focal spot: 0.5~2mm.

X-ray absorption fine structure Spectrum (XAFS) is a powerful tool for studying the local atomic or electronic structure of materials, widely used in popular fields such as catalysis, energy, and nanotechnology. The principle of X-ray absorption fine structure Spectrum(XAFS): X-ray absorption fine structure Spectrum refers to high-resolution spectra near the characteristic edges of atomic core electrons absorbing X-rays. When the energy of X-rays is the same as the excitation energy of the inner shell electrons of the measured element, they will be strongly absorbed, resulting in an absorption limit (or absorption edge). Near the absorption edge, due to multiple scattering and other reasons, the absorption coefficient of X-rays will exhibit oscillatory phenomena, namely fine structure. 2. Core advantages of X-ray absorption fine structure Spectrum(XAFS): (1) The highest luminous flux product, with a photon flux exceeding 1000000 photons/second/eV, and a spectral efficiency several times higher than other products; Obtain data quality equivalent to synchrotron radiation (2) Excellent stability, monochromatic light intensity stability of the light source is better than 0.1%, and repeated energy drift is less than 50 meV (3) 1% detection limit, high light flux, excellent optical path optimization, and excellent light source stability ensure that high-quality EXAFS data can still be obtained when the measured element content is>1%. 3. Application areas of XAFS: Industrial catalysis, energy storage materials, nanomaterials, environmental toxicology, qualitative analysis, heavy element analysis, etc. 4. Main features of XAFS: (1) Short range ordering: EXAFS depends on short-range interactions and does not rely on long-range ordering. XAFS can be used to study the structure of disordered systems such as amorphous, liquid, molten, and catalyst active centers. (2) Element specificity: Fluorescence method can be used to measure samples of elements with concentrations as low as one millionth. By adjusting the incident X-ray energy, the neighboring structures of atoms of different elements in the same compound can be studied. (3) Polarization characteristics: Polarized X-rays can be used to measure atomic bond angles and surface structures in oriented samples. The X-ray absorption fine structure Spectrum, with its unique principles, significant characteristics, and wide application fields, has become an indispensable and important tool in multiple fields such as materials science, catalytic chemistry, and energy research, providing strong support for in-depth exploration of material microstructures and electronic states.

The automatic sample changer used in X-ray diffractometers is a device used for automated sample replacement, aimed at improving the efficiency and accuracy of X-ray diffraction experiments. Driven by an imported stepper motor and controlled by an imported Siemens programmable logic controller (PLC), there is no need for manual sample replacement. The system automatically measures samples continuously and saves data automatically. Multiple samples can be loaded at once for continuous measurement. The main components of an automatic sample changer are: Sample transfer mechanism: usually includes a conveyor belt, elastic pressing plate, and driving motor, responsible for sequentially transferring the test sample plates to the retrieval position. Sample replacement mechanism: generally composed of clamping components, action driving components, and turntable, it can automatically replace the sample plate between the conveyor belt pick-up position and the diffraction instrument sample stage. Sensor module: such as photoelectric sensor module and photoresistor sensor module, used to detect the position of the sample and the working status of the diffractometer, in order to control the circuit module to make corresponding control actions. Control circuit module: Connect and control the collaborative work of the above-mentioned mechanisms and modules to ensure accurate and stable operation of the automatic sample changing process. Power module: provides power support for the entire automatic sample changing device. 2. Working principle of automatic sample changer: After the diffractometer completes the testing of the current sample, the sensor module detects the state change of the diffractometer shutter light and transmits the signal to the control circuit module. After receiving the signal, the control circuit module activates the sample replacement mechanism to move it to the conveyor belt pick-up position and the diffraction instrument sample stage, and clamps the sample plates at the two positions respectively through the clamping parts. Then, the sample replacement mechanism swaps the positions of the two sample plates to complete the sample replacement operation. Next, the conveyor belt starts and transports the next sample board to the pick-up position, waiting for the next sample change. 3. Advantages and characteristics of automatic sample changers: • Improve testing efficiency: It can automatically replace samples during the diffraction instrument testing process without manual intervention, greatly shortening the testing cycle and improving work efficiency. • Reduce human error: avoid operational errors and mistakes that may occur when manually replacing samples, and improve the accuracy and reliability of test results. • Instrument protection: reduces the possibility of instrument failure caused by frequent manual opening and closing of the diffractometer door, and extends the service life of the diffractometer. • Suitable for testing a large number of samples: It can load multiple samples to meet the needs of continuous testing of a large number of samples, and is suitable for high-throughput detection in fields such as scientific research and production. In summary, the automatic sample changer used in X-ray diffraction instruments is an efficient and accurate automated equipment that brings many conveniences and advantages to X-ray diffraction experiments, helping to improve experimental efficiency and quality.