The difference between single crystal XRD and powder XRD

2023-09-15 10:00X-ray diffractometer (XRD) can be divided into X-ray powder diffractometerand X-ray single crystal diffractometer, the basic physical principle of the two is the same.

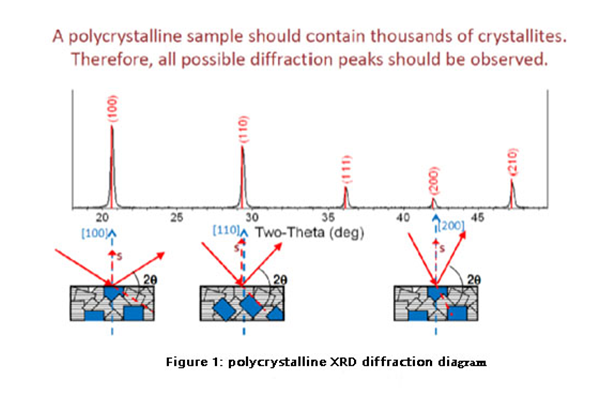

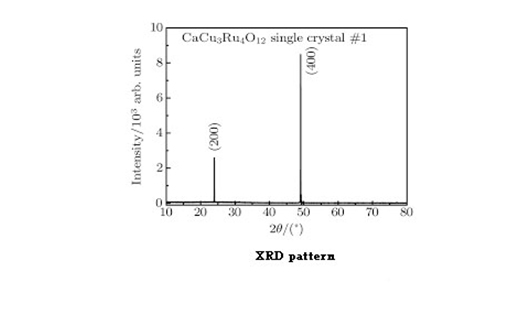

In practical applications, powder XRD measures the X-ray signals from all grains on the sample surface that meet the Bragg equation, which is an average effect (Figure 1). Because the polycrystalline orientation of the powder is disorderly and disorganized, regardless of how the crystals are placed, there are diffraction peaks on each crystal surface. As long as the angle is appropriate, diffraction peaks can occur on crystal surfaces that are highly diffractive and non extinction. Therefore, there are many peaks, such as many crystal surface peaks such as 001110111 in cubic crystals. For single crystals, the entire crystal has only one orientation, and the crystal plane has only one arrangement. Therefore, depending on the orientation of the samples, only diffraction peaks in one direction and multi-level diffraction peaks can be seen. For example, when placed in the direction of cubic crystal 001, only very sharp diffraction peaks such as 001002003 can be seen (Figure 2).

At each different diffraction Angle, there are a large number of grains satisfying the Bragg equation, and the diffraction signal from them eventually contributes to a certain XRD peak.

By comparing with the standard cards in the pdf card library, you can get qualitative and quantitative results about the phase. For single crystals, it is mainly used to determine the crystal structure of a single pure substance, for known structures, it can be refined, and for unknown structures, it can identify the structure. It is required that the sample to be measured is a block single crystal. In general, when characterizing new compounds, it is best to use a single crystal diffractometer. In addition, it is not easy to cultivate single crystals, and the growth of single crystals is limited by many conditions.

Rigaku has a series of products specially used for single crystal diffraction, Figure 3 is one of them. They all have high-intensity and high-collination X-ray sources, and the sample can be rotated in multiple dimensions. Through the clever software process, the process of single crystal testing is greatly simplified, saving the time of adjustment, and avoiding the errors and errors introduced by too many human operations.