News

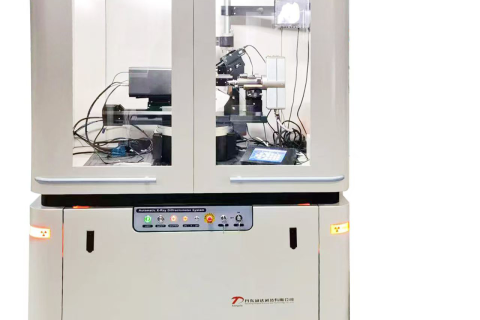

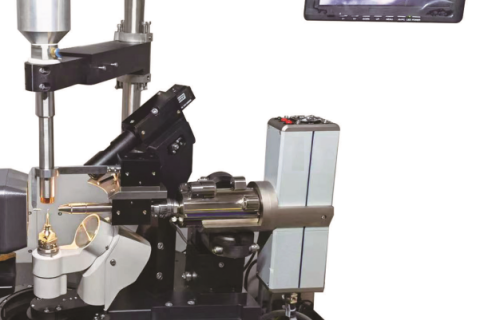

The Cryostream Low Temperature Liquid Nitrogen Cooling System (TD-100) used in single crystal X-ray diffractometers offers a range of features, from highly stable and precise temperature control to fast cooling times and integrated automatic filling capabilities. Each iteration of Cryostream expands the list of available functions. It combines elegant design, emphasizing reliability, simplicity, and ease of use. The latest version of the open flow low-temperature gas cooler integrates the controller, pump, and dry air unit into one gas supply module. This minimizes the overall system footprint, simplifies wiring and installation, and improves user experience.

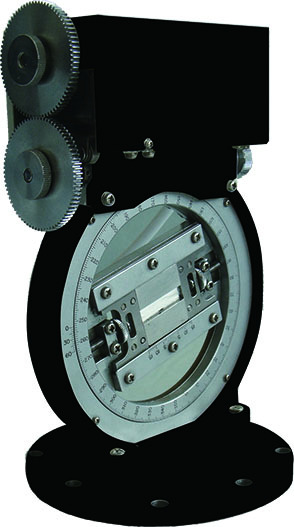

The corresponding accessories can be configured for small angle diffraction, and the angle range from 0 ° to 5 ° can be used for thickness testing of nano multilayer films.

Using X-ray diffraction (transmission) method to test the unique crystal structure of fibers. Test the orientation of the sample based on data such as fiber texture and half peak width.

Driven by an imported stepper motor and controlled by an imported Siemens programmable logic controller (PLC), there is no need for manual sample replacement. The system automatically measures samples continuously and saves data automatically. Six samples can be loaded at once for continuous measurement.

Dandong Tongda Technology Co., Ltd. is a professional manufacturer of X-ray products, with two main series of products: X-ray analysis instruments and X-ray non-destructive testing instruments. And in 2013, it became the undertaking unit of the X-ray single crystal diffractometer project of the National Major Scientific Instrument and Equipment Development Special Project of the Ministry of Science and Technology. Our company adheres to the principles of customer first, product first, and service first, insists on people-oriented, and has a strong technology team. We are committed to providing users with the highest quality high-tech products with advanced technology, and providing strong support and services to users with efficient technical consulting and after-sales service institutions.

The data collected through low-temperature equipment yields more ideal results. With the help of low-temperature equipment, more advantageous conditions can be provided, which can enable undesirable crystals to obtain ideal results, as well as ideal crystals to obtain more ideal results.

X-ray diffractometer is mainly used for phase qualitative and quantitative analysis, bulk structure analysis, material structure analysis, crystal orientation analysis, macroscopic or microscopic stress determination, particle size determination, crystallinity determination, etc. of powder, block or film samples.

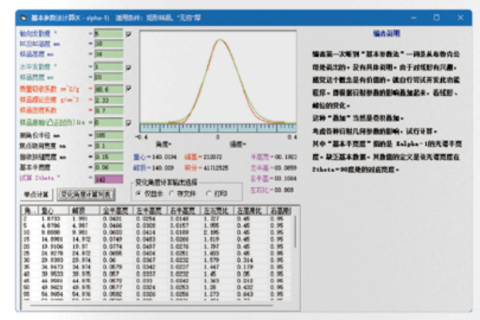

Software feature description:This program is a self-developed program. It contains various quantitative methods developed independently, in accordance with diffraction theory, and calculated entirely using integrated intensity.Analysis function. If this program contains the function of full spectrum peak fitting, separation and quantification that can still be accurately quantified under different phase line widths; as The function of the integrated intensity quantification method, which can conveniently automatically eliminate the interference of overlapping peaks of this phase and other phases, and is not affected by the different line widths of each phase, such as Complete PDF file calculation spectrum combination full spectrum fitting method, custom card file calculation spectrum combination full spectrum fitting method, etc. All the above methods use integration. The concept of intensity can be quantified by full spectrum fitting without involving structure and with different phase line widths. Can exclude overlapping peaks.Interference can reduce or eliminate the influence of preferred orientation.

Dandong Tongda Technology Co., Ltd. is a professional manufacturer of X-ray products, with two main series of products: X-ray analysis instruments and X-ray non-destructive testing instruments. And in 2013, it became the undertaking unit of the national major scientific instrument and equipment development special X-ray single crystal diffractometer project of the Ministry of Science and Technology of China. Our company adheres to the principles of customer first, product first, and service first, insists on people-oriented, and has a strong scientific and technological team. We are committed to providing users with the highest quality high-tech products with advanced technology, and providing strong support and services with efficient technical consulting and after-sales service institutions.

Excellent detector, polycrystalline sample X-ray diffraction analysis, precise instrument tuning, excellent resolution