News

X-ray diffractometer is mainly used for phase qualitative and quantitative analysis, crystal structure analysis, material structure analysis, crystal orientation analysis, macroscopic or microscopic stress determination, grain size determination, crystallinity determination, etc. of powder, block or film samples.

The TD series crystal analyzer adopts a vertical tube sleeve, and four windows can be used simultaneously. Adopting imported PLC control technology, it has high control accuracy and good anti-interference performance, which can achieve reliable operation of this system. PLC controls high voltage switches and lifting. It has the function of automatically training X-ray tubes, effectively extending the service life of X-ray tubes and instruments.

The TD series X-ray crystal analyzer is a large-scale analytical instrument used to study the internal microstructure of materials. It is mainly used for single product orientation, defect inspection, determination of lattice parameters, determination of residual stresses, study of the structure of plates and rods, and investigation of the structure of unknown substances and single crystal dislocations.

The use of hybrid pixel detector can achieve the best data quality while ensuring low power consumption and low cooling. This detector combines the key technologies of single photon counting and hybrid pixels, and is applied in various fields such as synchrotron radiation and conventional laboratory light sources, effectively eliminating the interference of readout noise and dark current. Hybrid pixel technology can directly detect X-rays, making it easier to distinguish signals, and detector can efficiently provide high-quality data.

The high-precision multifunctional angle measuring instrument of Tongda Technology can not only measure conventional powder samples, but also test liquid samples, colloidal samples, viscous samples, loose powders, and large solid samples.

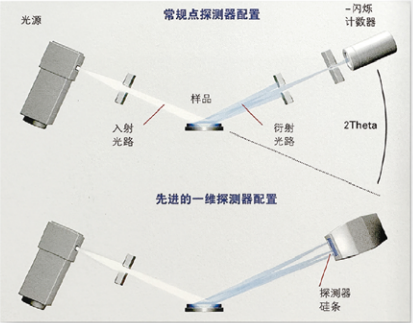

The goniometer is the heart of the X-ray diffractometer, and the TD series X-ray diffractometer has extremely high measurement accuracy

The goniometer is the heart of the X-ray diffractometer, and the TD series X-ray diffractometer has extremely high measurement accuracy

The TD series X-ray diffractometer inherits its consistent high stability and high-precision closed-loop vector driven servo positioning technology, further improving accuracy. In addition to upgrading traditional performance such as plug and play optical path with triple protection, the TD-3700 also incorporates vertical hollow axis and HPC hybrid photon counting technology, making it a representative of the new generation of X-ray diffractometers and one of the best X-ray polycrystalline diffractometers in the world.

We not only provide products, but as a carrier, we pay more attention to the convenience, efficiency, accuracy, and satisfaction that it can bring to our customers' actual work. This is our commitment that we have always upheld. As the most advanced domestically produced X-ray diffractometer, TD-3500 has benefited organizations such as colleges, research institutions, and industrial enterprises in material identification and analysis, receiving high praise. This also confirms our commitment to customer satisfaction. Of course, with the rapid pace of the times and competition, in order to ensure higher customer expectations, we continuously update and improve our product line. Our goal is not only to lead domestically, but also to keep up with the world!