The application of XRD in refractories

2023-12-12 10:001.Check the purity of raw materials

For example, silica powder may be added to metallic silicon as silicon, brown corundum may be added as brown wine bottle end, metallic aluminum powder may be added as solid after crushing cast aluminum, and Mg-Al spinel may be added as MgO.

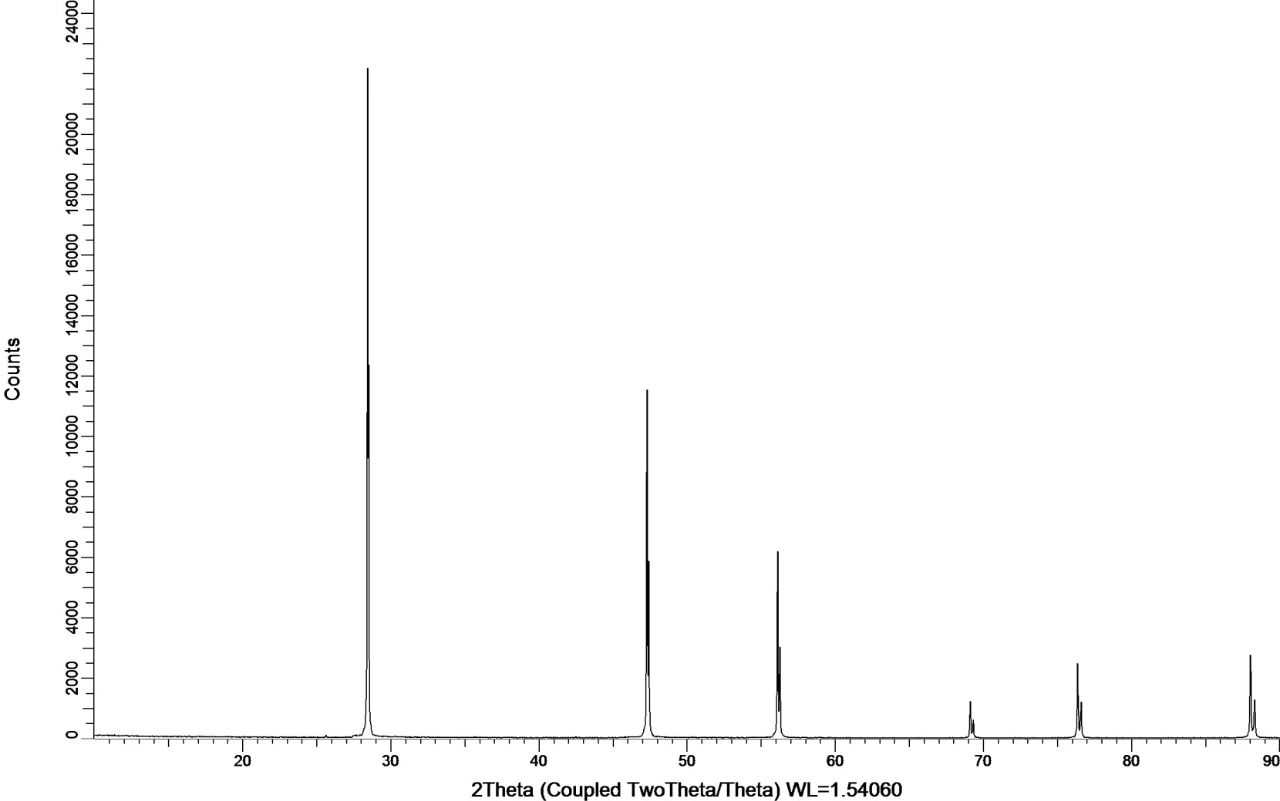

Fig(A)

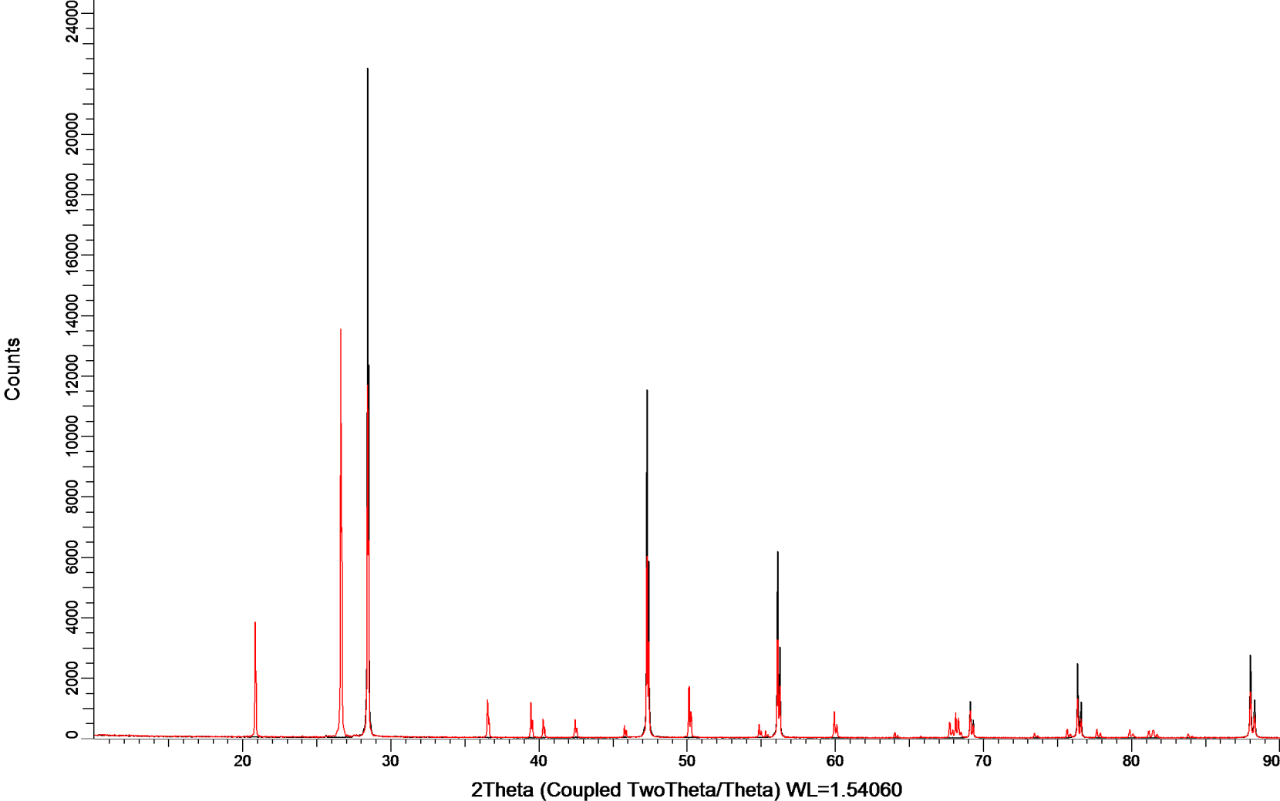

Fig(B)

The diffraction spectrum diagram (A) of pure Si powder can be seen from the XRD curve. The diffraction curve of Si powder with SiO2 added is shown in Figure (B).

2. Production process control

The production process of refractory requires control of the temperature and time of the production process to obtain the target product without impurities. XRD can help users confirm whether they have the desired product.

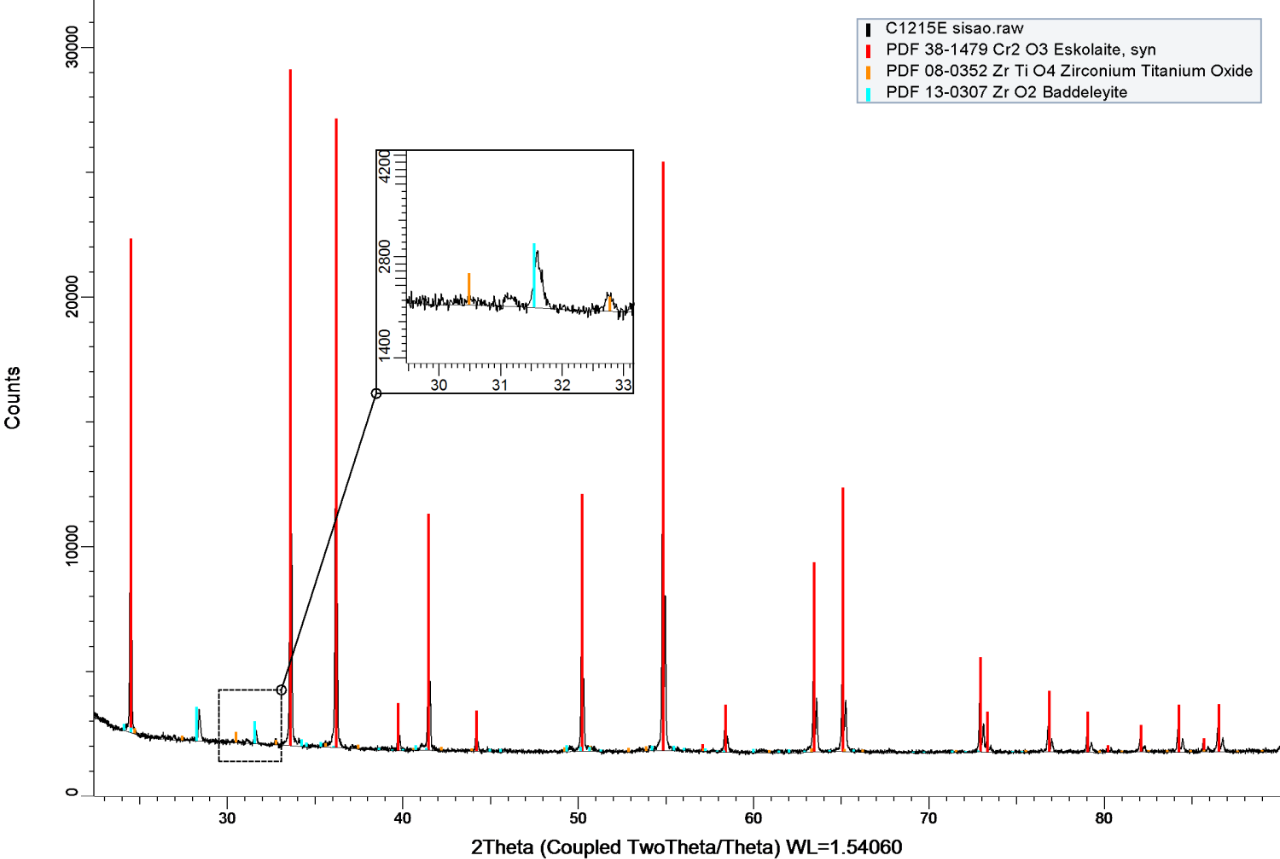

Fig(C)

As shown in Figure (C), the product was found to contain ZrTiO4(the peak corresponding to the yellow vertical line) by XRD inspection.

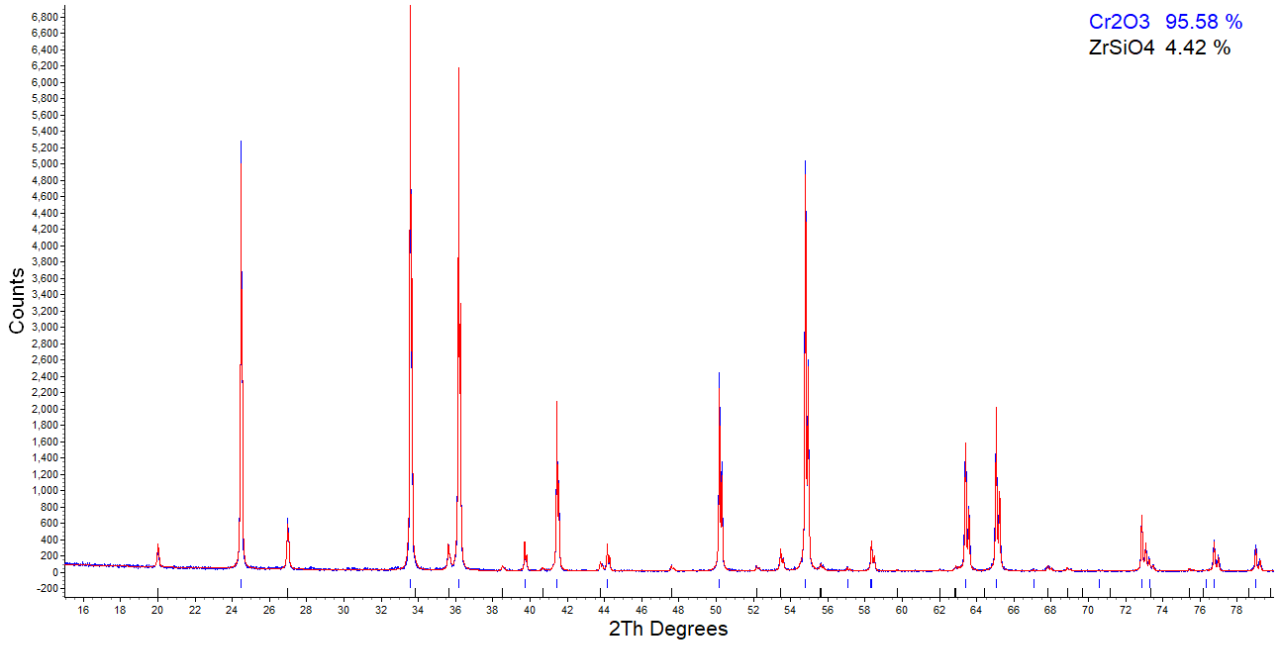

3. Product ingredient content analysis

The content of crystalline phase, amorphous phase and solid solution can be analyzed by XRD curve.

![]()