- Home

- >

News

X-ray Absorption Fine Structure(XAFS) is a powerful tool for studying the local atomic or electronic struct ure of materials based on synchrotron radiation light source.

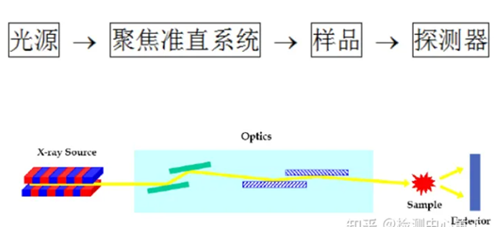

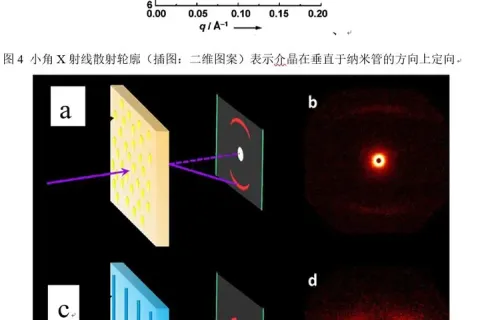

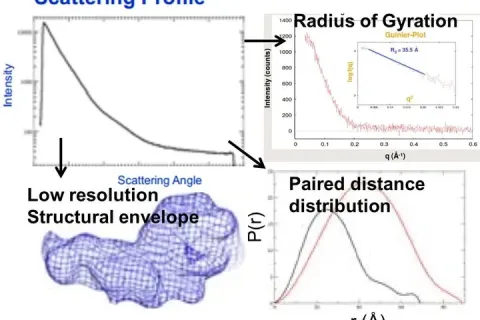

When a beam of extremely thin X-rays passes through a material with an uneven electron density of nanometer size, the X-rays will spread out in a small angular region near the direction of the original beam, this phenomenon is called small-angle X-ray scattering.

Small-angle X-ray scattering is the diffuse scattering of electrons to X-rays in the small Angle range near the original beam. Small-angle scattering occurs in all materials with non-uniform electron density on the nanometer scale.

Small Angle X-ray diffraction (SAXD) is mainly used to determine the spacing of very large crystal faces or the structure of thin films.

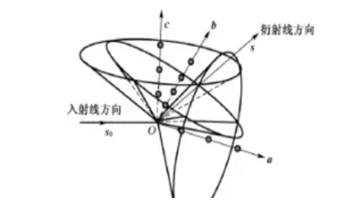

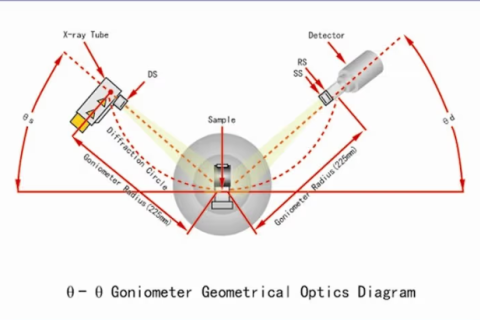

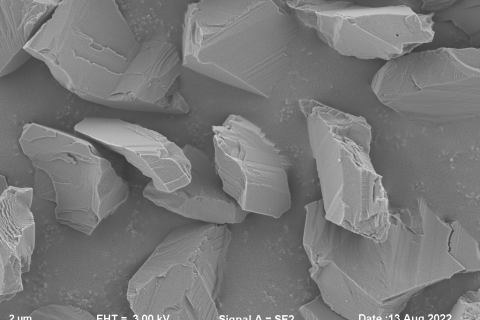

The use of X-rays to study the structure of crystals mainly through the X-ray diffraction phenomenon in the crystal.

X-ray diffraction technique is an analytical method used to study the structure of a substance. It determines the structure of a crystal by measuring the Angle of X-ray diffraction in the crystal.

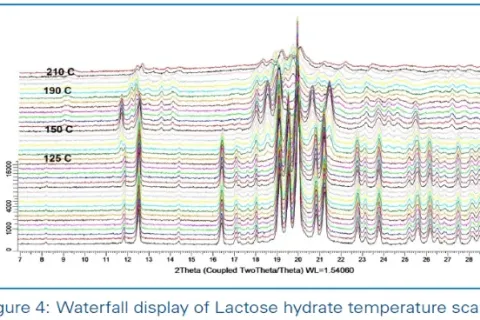

In-situ XRD, also known as In situ X-ray Diffraction, is a technique for making X-ray diffraction measurements during a structure or phase transition. This technology can monitor the dynamic change of the structure of the material under external force in real time.

Powder X-ray diffraction, as one of the methods for the study of drug polymorphism, has the advantages of not destroying samples and simple operation, and is the main method for the qualitative and quantitative analysis of drug polymorphism at present.

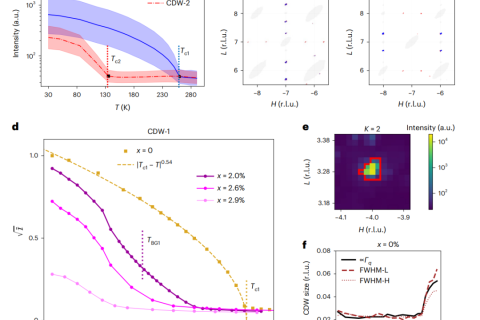

The Bragg glass phase is a near-perfect crystalline phase with glassy characteristics that is expected to occur in vortex lattices and charge density wave systems in the presence of disorder.

X-ray frequency and energy is second only to gamma rays, with penetration, frequency range 30PHz~300EHz, corresponding wavelength of 1pm~10nm, energy of 124eV~1.24MeV. Let's take a look at the properties and applications of X-rays.

This paper introduces the related knowledge of crystal pattern and crystal fetish

The X-ray intensity of nondestructive testing at a point in space is the sum of the number of photons and the energy product over a unit area perpendicular to the X-ray propagation direction in unit time.