News

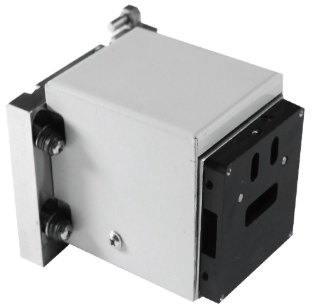

The X-ray crystal orienter operates based on the principle of X-ray diffraction. The high voltage generated by the high-voltage transformer acts on the X-ray tube, producing X-rays. When the X-ray is irradiated onto the sample, diffraction occurs when the Bragg diffraction condition (n λ=2dsin θ) is satisfied. Among them, λ is the wavelength of X-rays, d is the spacing between atomic planes inside the crystal, and θ is the angle between the incident X-rays and the crystal plane. The diffraction line is received by the counting tube and displayed on the microampere meter of the amplifier. When using a monochromator, the diffraction line is monochromatized and then received by the counter and displayed on the microampere meter of the amplifier, thereby improving measurement accuracy. The X-ray crystal orienter can accurately and quickly determine the cutting angle of natural and artificial single crystals (piezoelectric crystals, optical crystals, laser crystals, semiconductor crystals), and is equipped with a cutting machine for directional cutting of the above-mentioned crystals. X-ray crystal orienter is an indispensable instrument for precision machining and manufacturing of crystal devices. The X-ray crystal orienter is widely used in the research, processing, and manufacturing industries of crystal materials. The X-ray crystal orienter is easy to operate, does not require professional knowledge or skilled techniques, displays the angle digitally, is easy to observe, and reduces reading errors. The display of the X-ray crystal orientation instrument can be zeroed at any position, making it easy to display the deviation value of the chip angle. The dual angle measuring instrument can work simultaneously, improving efficiency. The X-ray crystal orienter has a special integrator with peak amplification, which improves the detection accuracy. The integration of X-ray tube and high-voltage cable increases high-voltage reliability. The detector high-voltage adopts DC high-voltage module and vacuum suction sample board, which improves the angle measurement accuracy and speed. Overall, the X-ray crystal orienter is a precision instrument based on the principle of X-ray diffraction, which provides important technical support for crystal material research and related applications by accurately measuring the cutting angle of crystals.

The Small angle diffractometer accessories are important accessories used in X-ray diffractometers. Small angle diffractometer accessories enable X-ray diffraction measurements to be taken within a very small angle range, from 0°to5°, for thickness testing of nano multilayer films. Plays an important role in fields such as materials science, physics, chemistry, and biology. Common types and characteristics: Parallel light thin film accessory: This accessory can generate parallel X-ray beams and is suitable for small angle diffraction measurements of thin film samples. It can improve the accuracy and resolution of measurements, reduce measurement errors caused by beam divergence, and better adapt to thin film samples of different thicknesses and properties. Multi functional sample stage: Equipped with small angle diffraction accessories, the multifunctional sample stage can provide various testing environments for samples, such as in-situ heating, cooling, stretching, etc. This makes it more convenient to study the structural changes of materials under different external conditions, and enables real-time observation of the structural response of materials during temperature, stress, and other changes. The Small angle diffractometer accessories play important role in multiple fields such as materials science, physics, chemistry, and biology by achieving small angle diffraction and precise measurement of nano multilayer film thickness, providing researchers with a powerful tool for in-depth exploration of material microstructures and properties.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber crystallinity and half peak width. A specialized component used for analyzing fiber materials such as textiles, polymer fibers, biological fibers, etc. It is commonly used to study the crystal structure, orientation, and molecular arrangement of fibers. Main functions of fiber accessories: 1. Fiber sample fixation: Fiber accessories are used to fix the fiber sample, ensuring its position and direction stability in the X-ray beam. 2. Fiber orientation analysis: By adjusting the position and angle of the sample, the crystal orientation and molecular arrangement of the fibers are studied. 3. Small angle X-ray scattering (SAXS): Some fiber attachments support SAXS for analyzing the nanoscale structure of fibers. Common types of fiber accessories: 1. Fiber stretching device: It can apply tension to fibers during XRD analysis to study structural changes under stress. 2. Rotating sample stage: allows fiber samples to rotate, facilitating the collection of diffraction data from different angles. 3. Temperature control accessories: used to analyze fiber materials at specific temperatures and study the effect of temperature on structure. Application fields of fiber accessories: 1. Materials Science: Study the crystal structure and mechanical properties of synthetic fibers such as nylon and polyester. 2. Biomaterials: Analyze the structure of natural fibers such as collagen and cellulose. 3. Textiles: Evaluate the orientation and crystallinity of textile fibers. Steps for using fiber accessories: 1. Sample preparation: Fix the fiber sample onto the attachment. 2. Adjust parameters: Set the X-ray source, detector, and sample positions. 3. Data collection: Collect diffraction patterns. 4. Data analysis: Use software to analyze diffraction data and obtain structural information. Matters needing attention: -Sample alignment: Ensure that the sample is accurately aligned with the X-ray beam. -Parameter optimization: Optimize X-ray energy, exposure time, etc. based on sample characteristics. -Data quality: Ensure clear diffraction patterns and avoid noise interference. Our company provides on-site training on instrument usage and related industry knowledge, as well as subsequent analysis software usage and maintenance, and complete machine maintenance services.

The TDM-20 Benchtop X-ray diffractometer uses a new high-performance array detector, and the loading of this detector has greatly improved the overall performance of the machine. The TDM-20 Benchtop XRD is mainly used for phase analysis of powders, solids, and similar paste like materials. The TDM-20 Benchtop X-ray diffractometer utilizes the principle of X-ray diffraction to perform qualitative or quantitative analysis, crystal structure analysis, and other polycrystalline materials such as powder samples and metal samples. Benchtop XRD is widely used in industries such as industry, agriculture, national defense, pharmaceuticals, minerals, food safety, petroleum, education, and scientific research.

The TD-3700 high-resolution X-ray diffractometer is equipped with a variety of high-performance detectors such as high-speed one-dimensional array detectors, two-dimensional detectors, SDD detectors, etc. TD-3700 X-ray diffractometer integrates fast analysis, convenient operation, and user safety. The modular hardware architecture and customized software system achieve a perfect combination, making its failure rate extremely low, anti-interference performance good, and ensuring long-term stable operation of high-voltage power supply. TD-3700 X-ray diffractometer can increase the diffraction calculation intensity by tens of times or more, obtain complete high-sensitivity, high-resolution diffraction patterns and higher counting intensity in a shorter sampling period, and also support transmission data scanning. The resolution of transmission mode is much higher than that of diffraction mode, which is suitable for structural analysis and other fields. Diffraction mode has strong diffraction signals and is more suitable for routine phase identification in the laboratory.

The parallel optical film measuring accessory increases the length of the grating plate to filter out more scattered lines, which is beneficial for reducing the influence of the substrate signal on the results and enhancing the signal intensity of the film.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber texture and half peak width.

The TDF series X-ray crystal analyzer is a large-scale analytical instrument and X-ray instrument used to study the internal microstructure of materials. It is mainly used for single crystal orientation, defect inspection, determination of lattice parameters, determination of residual stress, study of the structure of plates and rods, study of the structure of unknown substances, and single crystal dislocations.

The TD-5000 X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; It can provide information on the crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation. X-ray single crystal diffractometer is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science. Single crystal XRD is a high-tech product under the National Major Scientific Instrument and Equipment Development Project of the Ministry of Science and Technology, led by Dandong Tongda Technology Co., Ltd., filling the gap in the development and production of single crystal x-ray diffractometer in China.

Powder X-ray diffractometer is mainly used for phase qualitative and quantitative analysis, crystal structure analysis, material structure analysis, crystal orientation analysis, macroscopic or microscopic stress determination, grain size determination, crystallinity determination, etc. of powder, block or film samples. The TD-3500 X-ray diffractometer produced by Dandong Tongda Technology Co., Ltd. adopts imported Siemens PLC control, which makes the TD-3500 X-ray diffractometer have the characteristics of high accuracy, high precision, good stability, long service life, easy upgrade, easy operation and intelligence, and can flexibly adapt to testing analysis and research in various industries!