- Home

- >

News

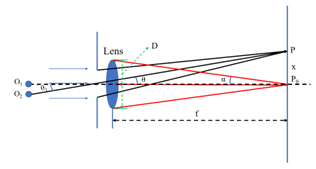

X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic,organic,and metal complexes,and to analyze the structure of special materials such as twinning, non commensurate crystals,quasicrystals,etc.Determine the accurate three-dimensional space (including bond length, bond angle,configuration,conformation,and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice;Single crystal X-ray diffractometer can provide information on the crystal cell parameters,space group,molecular structure,intermolecular hydrogen bonding and weak interactions,as well as structural information such as molecular configuration and conformation.Single crystal XRD is widely used in analytical research in chemical crystallography,molecular biology,pharmacology,mineralogy,and materials science. Single crystal XRD has high precision: 2θ angle repeatability accuracy: 0.0001°; Minimum step angle: 0.0001°; Temperature control range:100K-300K Control accuracy: ±0.3K Single crystal angle measuring instrument selects four concentric scanning circles. Single crystal XRD adopts low-temperature configuration. The company's technical personnel have completed the installation and debugging of the foreign single crystal X-ray diffractometer,and the test results have greatly satisfied foreign users. At the same time,the functionality,stability,and after-sales service of the instrument have received unanimous praise from foreign users. Overall, X-ray single crystal diffractometer plays an irreplaceable role as an important scientific instrument in research and application in multiple disciplines. With the continuous advancement and innovation of technology, we believe that in the future,single crystal XRD will demonstrate their unique value and potential in more fields.

The multi-function sample holder is a device used to provide flexibility and high efficiency in various scientific research and industrial applications. It is commonly used in X-ray diffraction (XRD) analysis and electron microscopy, and is an accessory of X-ray diffractometers (XRD accessory). As an accessory of X-ray diffractometers (XRD accessory) usually equipped with adjustable countertops to accommodate samples of different sizes and shapes.The multi-function sample holder is one of the indispensable tools in modern laboratories and research institutions. It greatly promotes the development of scientific research and industrial applications by providing a flexible, efficient, and accurate sample processing and analysis platform. Whether in the fields of materials science, biomedicine, or electronics industry, multifunction sample holder play an important role in helping researchers and engineers better understand and improve their research subjects.

Multi-function Sample Holder belongs to the X-ray diffractometer accessory(XRD accessory), which adopts advanced design technology and modular design ideas, and achieves functions such as rotation, lifting differential, and high-temperature oxidation resistance through the combination of different modules. Multi-function Sample Holder is suitable for various advanced thin film growth and deposition technologies, including MBE (molecular beam epitaxy), PLD (pulsed laser deposition), magnetron sputtering, and EB (electron beam evaporation), and can also be used for substrate annealing, high-temperature degassing, and material modification. The substrate of multi-function Sample Holder can reach a maximum heating temperature of 1100 ℃, and can be connected to RF/DC, with self rotation and a speed of 0-20 revolutions per minute. It is continuously adjustable and provides zero positioning. The modular design allows for multiple combination configurations to be selected, and the sample size can accommodate up to 8 inches. In summary, multi-function Sample Holder is a powerful and flexible experimental equipment, suitable for various scientific research and industrial applications as an X-ray diffractometer accessory (XRD accessory). The modular design and multiple functions of the multifunctional sample stage make it an indispensable tool in laboratories and industrial production.

The TD-5000 X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; Single crystal X-ray diffractometer can provide information on crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation. Single crystal XRD is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science. The single crystal diffractometer adopts the four circle concentricity technique to ensure that the center of the angle measuring instrument remains unchanged regardless of the rotation, achieving the goal of obtaining the most accurate data and obtaining higher integrity. Four circle concentricity is a necessary condition for conventional single crystal scanning. The company's technical personnel have completed the installation and debugging of the foreign single crystal X-ray diffractometer, and the test results have greatly satisfied foreign users. At the same time, the functionality, stability, and after-sales service of the instrument have received unanimous praise from foreign users.

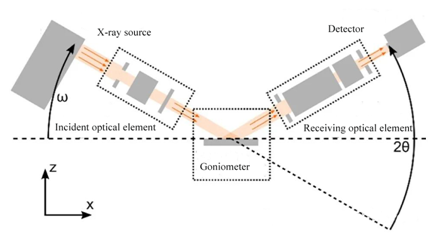

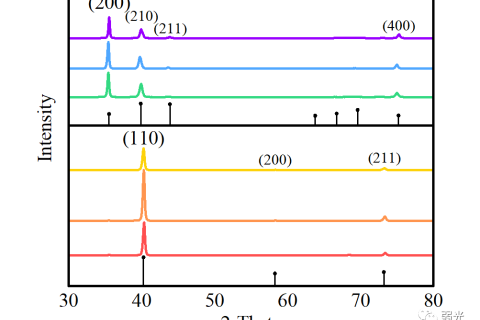

The TDM-20 desktop X-ray diffractometer is mainly used for phase analysis of powders, solids, and similar paste like materials.Benchtop XRD utilizes the principle of X-ray diffractometer to perform qualitative or quantitative analysis, crystal structure analysis, and other polycrystalline materials such as powder samples and metal samples. The TDM-20 desktop X-ray diffractometer is widely used in industries such as industry, agriculture, national defense, pharmaceuticals, minerals, food safety, petroleum, education, and scientific research. The loading of a new high-performance array detector has led to a significant improvement in the performance of benchtop XRD。 Benchtop XRD equipment has a small volume and light weight; The working power of the Benchtop XRD high-voltage power supply can reach 1600 watts; Benchtop XRD can quickly calibrate and test samples; Benchtop XRD circuit control is simple and easy to debug and install; The repeatability of the Benchtop XRD angle can reach 0.0001.

The TD-RSD X-ray Diffraction Residual Stress Analyzer integrates multiple diffraction geometries and high-precision detection technologies. It enables accurate residual stress analysis in metals, ceramics, and composites, featuring 3kW power, ±7MPa repeatability, and automated operation for industrial and research applications.

Dandong Tongda Science and Technology Co., Ltd. is a leading manufacturer of X-ray analysis and non-destructive testing equipment. As a national high-tech enterprise, we provide cutting-edge products like TD-series X-ray diffractometers and automated sample changers. Our customer-centric philosophy ensures comprehensive pre-sales, during-sales, and after-sales support, including technical consultations, professional training, and lifelong maintenance. We deliver complete solutions for materials science, industrial production, and environmental monitoring, backed by a reliable service system. Contact: +86-415-6123805 / firefly@tongdatek.com

Tongda Tech attracts talent by creating a vibrant "home & playground" workplace. With recreational facilities and team activities, it fosters relaxation, teamwork and innovation. This balance boosts satisfaction, reduces turnover and drives shared growth.

X-ray diffraction is a method to study the phase and crystal structure of a substance by using the diffraction phenomenon of X-rays in a crystal.

X-ray diffraction technique is often used to detect the crystal quality of wafers and epitaxial wafers.

XRD qualitative detection is convenient, fast and less interference. With the continuous innovation of technical means, X-ray diffraction technology has a broader application prospect in the field of material analysis.

X-ray diffraction, through the X-ray diffraction of a material, the analysis of its diffraction pattern, to obtain the composition of the material, the structure or shape of the atoms or molecules inside the material and other research means.