- Home

- >

News

Founded in 2002, Dandong Tongda Technology Co., Ltd. is a national high-tech enterprise with X-ray analysis instruments and X-ray non-destructive testing instruments as its leading products

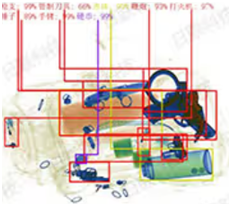

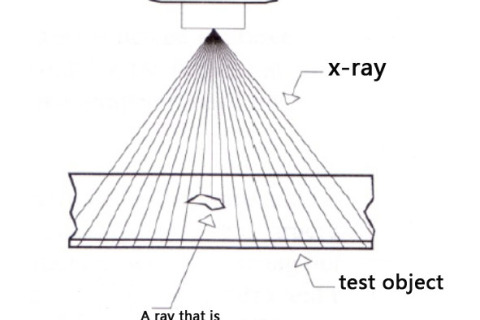

The X-ray transmission inspection can provide a picture of whether there are defects in the inspection site of the casting and the relevant size, and the X-ray inspection system is widely used in industrial production.

X-rays have a short wavelength and high energy, and can penetrate objects to directly observe internal defects. Highly praised in the field of non-destructive testing. In fact, there is another function that is also widely used, namely foreign body detection.

Nowadays, X-ray imaging technology has formed a relatively complete X-ray non-destructive testing technology system. New detection technologies are also being innovated, using Xray online detection technology.

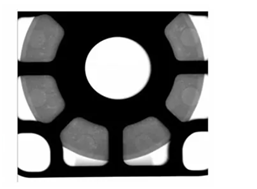

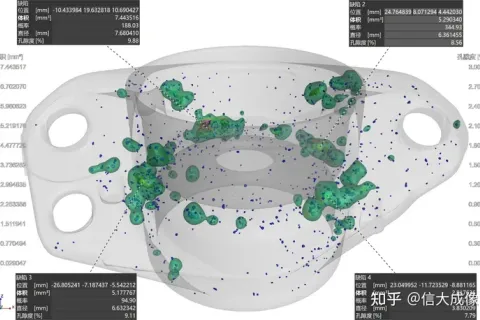

Industrial CT non-destructive testing is the judgment of internal defects, structural defects, physics and composition of the product under the original state and performance of the workpiece without destroying or changing the raw materials.

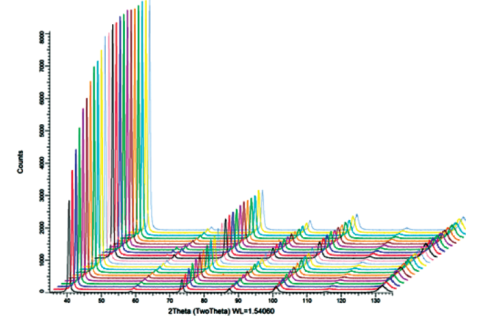

An X-ray diffractometer is an instrument used to measure residual stress inside a material. By analyzing the X-ray diffraction pattern of the material, the residual stress distribution inside the material is calculated.

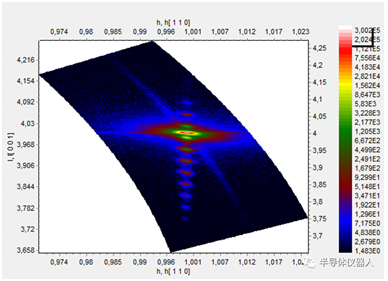

HRXRD is a powerful non-destructive testing method, and its research objects are mainly single crystal materials, single crystal epitaxial thin film materials and various low-dimensional semiconductor heterostructures.

In the development of X-ray imaging technology, X-ray imaging technology has formed a relatively complete X-ray non-destructive testing technology system. In order to meet the needs, new detection technology is constantly innovated, and X-ray online detection technology is adopted.

The previous one detailed and complete introduction of the company's pre-sale, sale and after-sales service, today introduced is our company's product training related content.

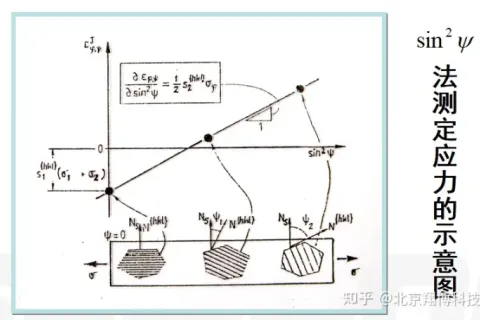

It is necessary to reduce the harmful residual stress and predict the distribution trend and value of residual stress. In this paper, the non-destructive testing method of residual stress testing is introduced.

Nondestructive testing is based on the development of modern science and technology. With the development of modern industry, the application of non-destructive testing is more and more popular.