What can Industrial CT nondestructive testing do?

2024-01-11 10:00Industrial CT non-destructive testing is to make judgments on internal defects, physics and composition of products without destroying or altering raw materials. At present, the application of non-destructive testing technology is mainly in the product manufacturing process detection, finished product detection and so on.

1. Non-destructive testing methods

Industrial CT scans use radiography to produce multiple two-dimensional images of an object. As the object being scanned rotates on the stage, X rays penetrate it to varying degrees, depending on its density. Radiation that cannot be absorbed by the part bounces back into the detector panel, producing hundreds of cross-sectional 2D x ray images, which are then reconstructed to create three-dimensional measurements.

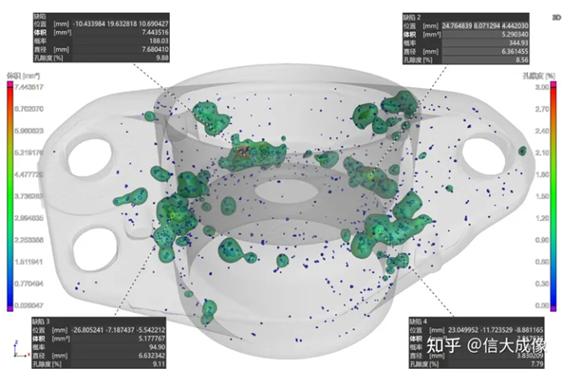

2. Internal and external measurement

Contact CMM, non-contact laser and structured light measurement technologies all have their advantages in recording shapes and dimensions, and CT scanning services will generate complete 3D datasets of external and internal geometry. In addition to 3D models built for various metrological and inspection applications, cross-sectional 2D images generated during industrial CT scans can also be analyzed. This can not only shorten the product development cycle, but also provide an efficient and simple method of quality control.