- Home

- >

News

Dandong Tongda's X-ray non-destructive testing equipment ensures precise internal inspection for aerospace, automotive and construction sectors. Featuring portable design and advanced safety systems, it delivers reliable defect detection while maintaining complete operational safety.

Non-Destructive Testing (NDT) is an indispensable quality assurance technology in modern industry. It enables the detection of internal defects, structures, and property conditions of materials by utilizing characteristics such as acoustic, optical, magnetic, and electrical properties—all without damaging or affecting the performance of the tested object. Compared to destructive testing, NDT has the following characteristics: First, it is non-destructive, as it does not impair the performance of the test object. Second, it is comprehensive. Since the testing is non-destructive, it allows for 100% full inspection of the test object when necessary, which is impossible with destructive testing. Third, it is full-process applicable. Destructive testing is generally only suitable for raw materials, such as tensile, compression, and bending tests commonly used in mechanical engineering. Destructive testing is conducted only on raw materials for manufacturing. For finished products and in-service equipment, destructive testing cannot be performed unless they are no longer intended for use. In contrast, NDT does not damage the test object’s performance, making it suitable for full-process testing, from raw materials and intermediate manufacturing stages to final products, as well as for in-service equipment. Among the many manufacturers of non-destructive testing equipment, Dandong Tongda Technology Co., Ltd. has developed a variety of NDT instruments that approach or achieve internationally advanced levels, thanks to its solid technical expertise and innovative capabilities. Technical Features: Portability, Safety, and Intelligence Tongda Technology's NDT Portable X-ray Welding Testing Machine exhibit several outstanding features. Their X-ray generators adopt an anode grounding and fan-forced cooling design, making them compact, lightweight, portable, and easy to operate. In terms of safety performance, the equipment is equipped with a delayed exposure function, effectively ensuring operator safety. The devices operate on a 1:1 work-rest cycle, with a rational duty cycle design that ensures detection efficiency while extending the equipment’s service life. The company’s products incorporate Programmable Logic Controller (PLC) technology and a modular design concept, enhancing automation, improving anti-interference capabilities, and ensuring an extremely low failure rate. Application Areas: Wide Adoption Across Multiple Industries Tongda Technology's NDT Portable X-ray Welding Testing Machine are suitable for various industrial sectors, including national defense, shipbuilding, petroleum, chemicals, machinery, aerospace, and construction. These instruments are used to inspect the welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges, as well as the internal quality of various lightweight metals, rubber, ceramics, and other materials.

Founded in 2002, Dandong Tongda Technology Co., Ltd. is a national high-tech enterprise with X-ray analysis instruments and X-ray non-destructive testing instruments as its leading products

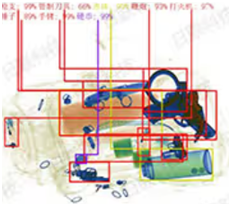

The X-ray transmission inspection can provide a picture of whether there are defects in the inspection site of the casting and the relevant size, and the X-ray inspection system is widely used in industrial production.

X-rays have a short wavelength and high energy, and can penetrate objects to directly observe internal defects. Highly praised in the field of non-destructive testing. In fact, there is another function that is also widely used, namely foreign body detection.

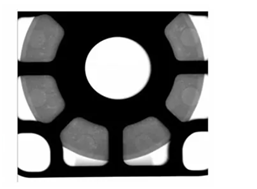

Nowadays, X-ray imaging technology has formed a relatively complete X-ray non-destructive testing technology system. New detection technologies are also being innovated, using Xray online detection technology.

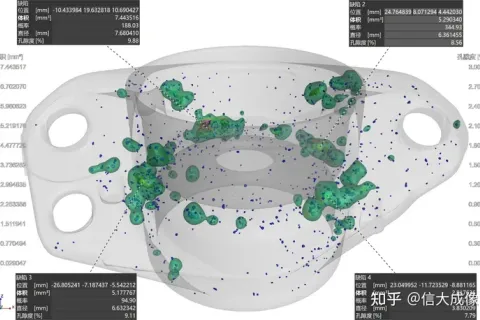

Industrial CT non-destructive testing is the judgment of internal defects, structural defects, physics and composition of the product under the original state and performance of the workpiece without destroying or changing the raw materials.

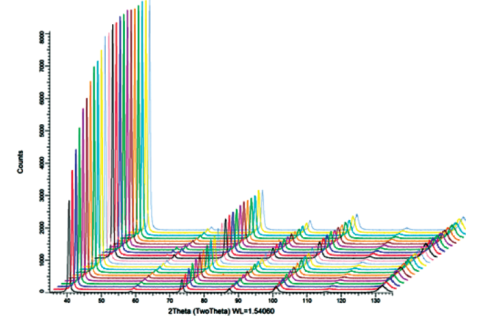

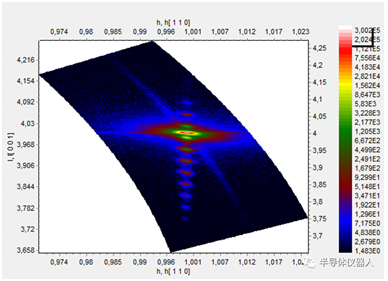

An X-ray diffractometer is an instrument used to measure residual stress inside a material. By analyzing the X-ray diffraction pattern of the material, the residual stress distribution inside the material is calculated.

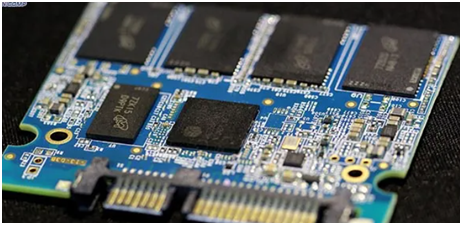

HRXRD is a powerful non-destructive testing method, and its research objects are mainly single crystal materials, single crystal epitaxial thin film materials and various low-dimensional semiconductor heterostructures.

In the development of X-ray imaging technology, X-ray imaging technology has formed a relatively complete X-ray non-destructive testing technology system. In order to meet the needs, new detection technology is constantly innovated, and X-ray online detection technology is adopted.

The previous one detailed and complete introduction of the company's pre-sale, sale and after-sales service, today introduced is our company's product training related content.