- Home

- >

- News

- >

- Industry news

- >

News

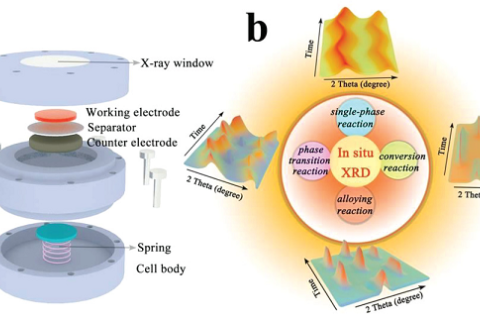

According to the position and intensity changes of in-situ XRD diffraction peaks, the intermediates generated during the cycle can be inferred, and the reaction mechanism can be further derived from these intermediates.

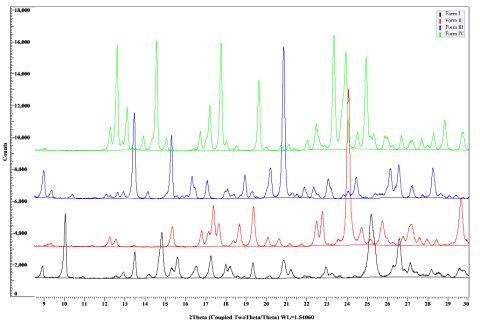

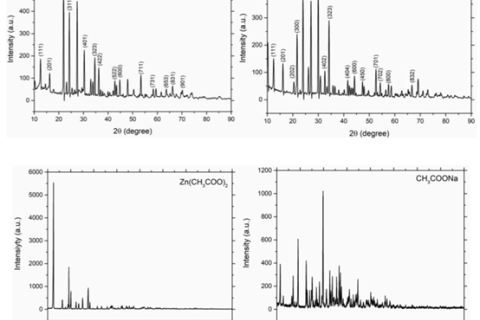

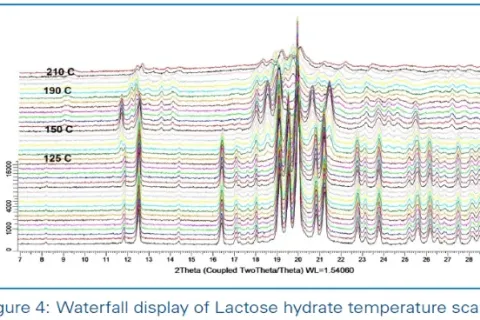

X-ray diffraction runs through every stage of drug quality control, such as the study of raw materials and preparations.

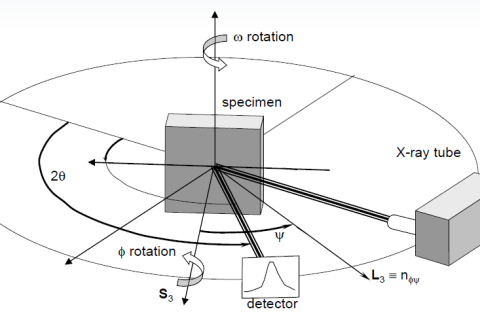

Residual stress has a great impact on the dimensional stability, stress corrosion resistance, fatigue strength, phase change and other properties of materials and components. Its measurement has been widely concerned by academia and industry.

XRD, is short for X-ray diffraction, as a material person, no matter what material is done, XRD is the most commonly used, the most basic means of characterization.

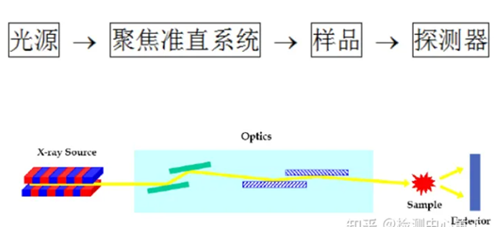

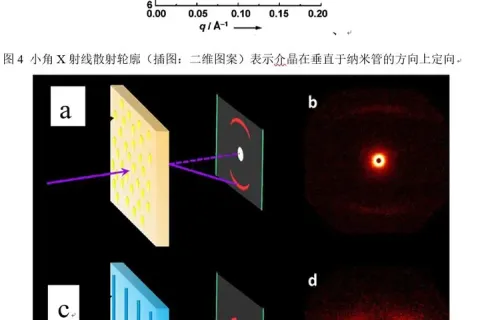

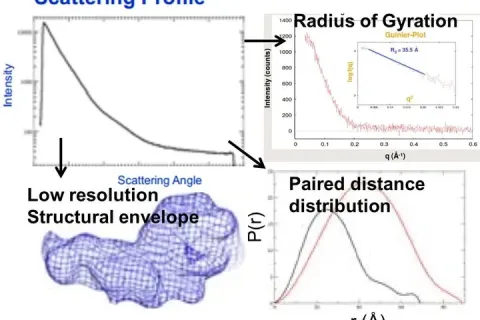

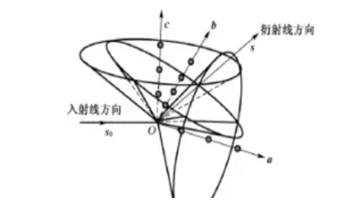

When a beam of extremely thin X-rays passes through a material with an uneven electron density of nanometer size, the X-rays will spread out in a small angular region near the direction of the original beam, this phenomenon is called small-angle X-ray scattering.

Small-angle X-ray scattering is the diffuse scattering of electrons to X-rays in the small Angle range near the original beam. Small-angle scattering occurs in all materials with non-uniform electron density on the nanometer scale.

Small Angle X-ray diffraction (SAXD) is mainly used to determine the spacing of very large crystal faces or the structure of thin films.

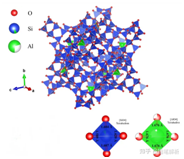

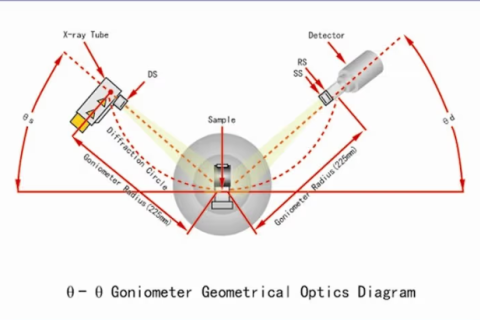

The use of X-rays to study the structure of crystals mainly through the X-ray diffraction phenomenon in the crystal.

X-ray diffraction technique is an analytical method used to study the structure of a substance. It determines the structure of a crystal by measuring the Angle of X-ray diffraction in the crystal.

In-situ XRD, also known as In situ X-ray Diffraction, is a technique for making X-ray diffraction measurements during a structure or phase transition. This technology can monitor the dynamic change of the structure of the material under external force in real time.