The residual stress was analyzed by XRD

2024-03-27 23:00Residual stress has a great impact on the dimensional stability, stress corrosion resistance, fatigue strength, phase change and other properties of materials and components. Its measurement has been widely concerned by academia and industry.

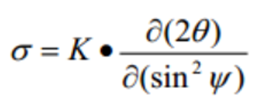

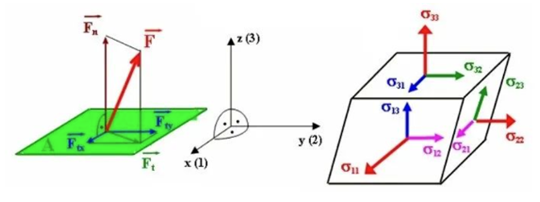

The basic principle of X-ray diffraction measurement of residual stress is based on measuring the deviation of the diffraction Angle, obtaining the strain, and then calculating the residual stress through elastic mechanics.

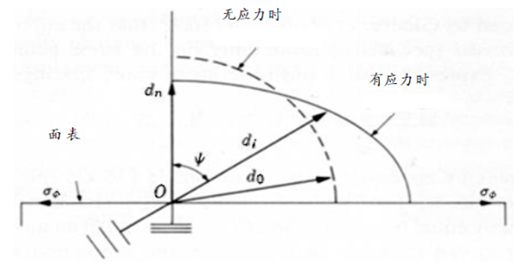

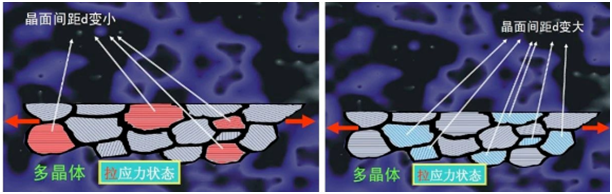

In the unstressed state, the diffraction Angle 2θ does not change with the change of the azimuth ψ of the crystal face. When there is residual stress in the sample, the distance between crystal faces will change. When Bragg diffraction occurs, the diffraction peak will also move, and the moving distance is related to the stress.

In the tensile stress state, the larger the crystal plane azimuth ψ, the larger the crystal plane spacing d, and the smaller the diffraction Angle 2θ according to Bragg's law. On the contrary, in the state of compressive stress, the larger the crystal face azimuth ψ, the smaller the crystal face spacing, and correspondingly, the larger the diffraction Angle 2θ.

According to Bragg's Law and elasticity theory, it can be deduced: