News

Special corrugated ceramic tubes, metal ceramic tubes, and glass tubes for analytical instruments, suitable for various models of XRD, XRF, crystal analyzers, and orientation instruments at home and abroad. An X-ray tube is a vacuum electronic device that generates X-rays by high-speed electron impact on a metal target material. Its structure, principle, and application involve various technical characteristics. 1. Basic structure of X-ray tube (1) Cathode (electron emission source) Composed of tungsten filament, X-ray tube heats up and emits electrons after being powered on, and is wrapped around a focusing cover (cathode head) to control the direction of the electron beam. The filament temperature is about 2000K, and the electron emission is regulated by current. (2) Anode (target material) Usually high melting point metals (such as tungsten, molybdenum, rhodium, etc.) are used to withstand high-energy electron bombardment and generate X-rays. Contains anode head (target surface), anode cap, glass ring, and anode handle, responsible for heat dissipation (through radiation or conduction) and absorption of secondary electrons. (3) Vacuum shell and window Glass or ceramic shell maintains a high vacuum environment (not less than 10 ⁻⁴ Pa) to avoid electron scattering. Window materials require low X-ray absorption, commonly using beryllium sheets, aluminum, or Lindemann glass. 2. Working principle of X-ray tube (1) Electron Acceleration and Impact The electrons emitted by the cathode filament are accelerated by high voltage (in the range of kilovolts to megavolts) and collide with the anode target material. The process of converting electronic kinetic energy into X-rays includes: Bremsstrahlung: Continuous spectrum X-rays released when electrons decelerate or deflect. Characteristic radiation: X-rays (such as Kα and Kβ lines) released by electron transitions in the inner layer of the target material. (2) Energy Conversion and Efficiency Only about 1% of the electron energy is converted into X-rays, and the remaining is dissipated in the form of heat, requiring forced cooling (such as a rotating anode design). 3. Classification and application scenarios of X-ray tubes (1) By generating electronic means Inflatable tube: an early type that relies on gas ionization to generate electrons, with low power and short lifespan (now obsolete). Vacuum tube: Modern mainstream, high vacuum environment improves electronic efficiency and stability. (2) By purpose In the medical field, diagnostic (such as dental and breast examinations) and therapeutic (such as radiotherapy) X-ray tube often use rotating anodes to increase power density. Industrial testing: non-destructive testing, material structure analysis, etc., with a focus on high penetration (hard X-rays). (3) According to the cooling method Fixed anode: simple structure, suitable for low-power scenarios. Rotating anode: The target surface rotates at high speed (up to 10000 revolutions per minute) to improve heat dissipation and support high-power output. 4. Performance characteristics and limitations of X-ray tubes (1) Advantages Low cost, small size, easy operation, suitable for routine medical and industrial testing. Flexible adjustment of target materials (such as tungsten, molybdenum, copper) to meet different energy requirements. (2) Limitations Poor brightness and collimation, large X-ray divergence angle, requiring additional collimators. The energy spectrum is continuous and contains characteristic lines, requiring filtering or monochromatization (such as using nickel filters to remove Kβ lines). 5. Comparison between X-ray tubes and synchrotron radiation sources (1) Brightness and flux X-ray tube: Low brightness, suitable for routine testing. Synchrotron radiation light source: with a brightness 106~1012times higher, suitable for cutting-edge research such as nanoimaging and protein crystallography. (2) Spectral characteristics X-ray tube: Discrete characteristic lines+continuous spectrum, energy range limited by acceleration voltage. Synchrotron radiation: wide continuous spectrum (from infrared to hard X-rays), precisely tunable. (3) Time characteristics X-ray tube: Continuous or microsecond level pulses (rotating target). Synchrotron radiation: Femtosecond level pulses, suitable for studying dynamic processes such as chemical reactions. 6. Technical parameters of X-ray tube (1) Optional target material types: Cu, Co, Fe, Cr, Mo, Ti, W, etc (2) Focus type: 0.2 × 12mm2 or 1 × 10mm2 or 0.4 × 14mm2 (fine focus) (3) Larger output power: 2.4kW or 2.7kW Overall, X-ray tube dominate in fields such as medical diagnosis and industrial testing due to their practicality and economy, but are limited by performance bottlenecks. For scenes that require high resolution and high brightness (such as cutting-edge scientific research), advanced technologies such as synchrotron radiation sources need to be relied upon. Future development directions include improving energy conversion efficiency, optimizing heat dissipation structures, and developing miniaturized X-ray sources.

The rotating sample holder is an experimental device used for precise control of sample orientation, widely used in fields such as X-ray diffraction (XRD), spectroscopic analysis, and material testing. By rotating the sample, preferred orientation can be eliminated, measurement accuracy and repeatability can be improved. 1. The core function of the rotating sample holder (1) Eliminating preferred orientation: By rotating the sample plane (β axis), diffraction errors caused by coarse grains or texture are reduced, ensuring the reproducibility of diffraction intensity. (2) Multi position measurement: Conduct multi angle measurements on uneven samples (such as grains), average the data at different positions, and improve the accuracy and repeatability of the results. (3) Automated operation: Some devices support automatic rotation and sample change to improve testing efficiency (such as XRD fully automatic rotating sample holder). 2. Technical characteristics of rotating sample holder (1) Structural design: Drive mode: precise rotation is achieved through mechanisms such as motors, shafts, gears and racks, and some equipment is equipped with servo motors and encoders to correct the speed. Clamping device: The sample is fixed by a compression clamp, card slot, or clamping block, and the inner side is partially clamped with a rubber layer to adapt to different materials. Rotation parameters: The rotation speed can reach 1-60RPM, with a minimum step width of 0.1 º, and supports continuous or step modes. (2) Adaptability: Can be installed in XRD instruments, optical/electrical testing systems, etc., supporting multiple sample holders (such as reflective probes, in-situ battery accessories, etc.). Some devices support 360°rotation and are compatible with various measurement requirements such as optics and electronics. 3. Application scenarios of rotating sample holder (1) X-ray diffraction (XRD): Used for analyzing samples with texture or crystallography (such as metal materials, thin films), to eliminate the influence of preferred orientation on diffraction results. The fully automatic model can improve the efficiency of multi sample testing, reduce the number of door opening and closing times, and extend the lifespan of equipment. (2) Spectral analysis and material testing: Used for measuring uneven samples (such as grains) with reflective probes, by rotating and averaging spectral data at different positions. Adapt to in-situ high and low temperature environments, and support complex experimental conditions. (3) Multi functional experiment: By combining probes, electrical or optical sample holders, comprehensive testing of electrical characteristics, surface morphology, and other features can be achieved. The rotating sample holder solves the measurement error problem caused by the preferred orientation of traditional fixed sample stages by accurately controlling the sample orientation. At the same time, its automation and multi scene adaptability make it a key tool in fields such as XRD and spectral analysis. The specific selection needs to be matched with the corresponding model based on experimental requirements such as rotation accuracy, sample type, and automation level.

Dandong Tongda Technology specializes in the development of small-angle diffraction attachments, which are dedicated components for X-ray diffractometers. Covering a diffraction angle range of 0° to 5°, these attachments enable precise measurement of nanoscale multilayer film thickness and support structural analysis of nanomaterials. Designed for seamless compatibility with TD-3500, TD-3700, and other series diffractometers, they are widely used for nanoscale material characterization in fields such as materials science, chemical engineering, geology, and mineralogy. Incorporating imported PLC control technology and modular design, these attachments significantly enhance equipment automation and operational stability. The TD series instruments now meet international standards and have been successfully exported to countries including the United States and Azerbaijan, providing crucial technical support for global nanomaterial research.

Dandong Tongda's Parallel Optical Film Measuring Accessory is a specialized component for X-ray diffractometers, significantly improving thin-film sample testing performance. Its elongated grating design effectively suppresses scattering interference, enhancing signal clarity for ultra-thin and nanomultilayer films. The accessory supports small-angle diffraction analysis (0°–5°), enabling precise measurement of film thickness and interface structures. Compatible with TD-3500, TD-5000, TD-3700, and TDM-20 diffractometers, it ensures consistent performance across platforms. Widely applied in semiconductor inspection, optical coating evaluation, and new energy material research, this tool addresses challenges like weak signals and background noise. As nanomaterials and semiconductor industries advance, the accessory is poised to play an increasingly critical role in cutting-edge research and quality control.

In situ medium and low temperature accessories are experimental equipment accessory used for material analysis, mainly used for in-situ testing in low or medium low temperature environments. Combined with vacuum environment, temperature control, and special window material design, it is widely used in fields such as chemistry, materials science, and catalytic research. 1. Core functions and technical parameters of in-situ medium and low temperature accessories (1) Temperature range and control accuracy Supports a temperature range of -196 ℃ to 500 ℃ in a vacuum environment (such as liquid nitrogen refrigeration), with a temperature control accuracy of ± 0.5 ℃. Some models can cover temperatures from -150 ° C to 600 ° C, suitable for a wider range of experimental needs. (2) Refrigeration method and cooling system Using liquid nitrogen refrigeration, with a liquid nitrogen consumption of less than 4L/h, and maintaining a stable temperature through a deionized water circulation cooling system. Optional low-temperature liquid nitrogen cooling system (such as Cryostream series). (3) Window Materials and Structural Design The window material is mostly polyester film (such as TD series), and some infrared configurations use KBr or SiO2 windows. The structure includes a high-pressure resistant design (such as 133kPa) and is equipped with multiple gas inlets/outlets, suitable for in-situ reactions or atmosphere control. 2. Application fields of in-situ medium and low temperature accessories (1) Material research Used for in-situ testing of X-ray diffractometers (such as TD-3500) to study changes in crystal structure and phase transition processes at low temperatures. Support research on heterogeneous catalysis, gas-solid interactions, photochemical reactions, etc. (2) Electrochemical and Battery Research It can be extended to in-situ battery accessories to test composites in electrochemical systems (such as carbon, oxygen, nitrogen, sulfur, etc.), with a temperature resistance of up to 400 ℃. (3) Industry Applications The products of Dandong Tongda Technology (TD series) have been applied in the fields of chemistry, chemical engineering, geology, metallurgy, etc., and exported to countries such as the United States and Azerbaijan. 3. Typical products and brands of in-situ medium and low temperature accessories Dandong Tongda Technology (TD Series) The accessories for X-ray diffractometers such as TD-3500 and TD-3700 emphasize high-precision temperature control (± 0.5 ℃) and efficient liquid nitrogen refrigeration. Suitable for diffuse reflectance spectroscopy measurement, providing stainless steel reaction chamber, multi window configuration (FTIR or UV Vis compatible), supporting high vacuum to 133kPa environment. Overall, in situ medium and low temperature accessories have become an important tool for material in situ analysis through precise temperature control, vacuum environment, and window design adapted to different instruments. They play an irreplaceable role in the study of low-temperature crystal structures and exploration of catalytic reaction mechanisms.

To understand the changes in crystal structure of samples during high-temperature heating and the changes in mutual dissolution of various substances during high-temperature heating. In situ high-temperature attachment is an experimental device used for in-situ characterization of materials under high temperature conditions, mainly used to study dynamic processes such as crystal structure changes, phase transitions, and chemical reactions of materials during high-temperature heating. The following provides a detailed introduction from the aspects of technical parameters, application scenarios, and precautions: 一、 Technical parameters of in-situ high-temperature attachments 1. Temperature range of in-situ high-temperature attachments Inert gas/vacuum environment: The maximum temperature can reach 1600 ℃. Standard environment: Room temperature to 1200 ℃ (as provided in the TD-3500 XRD accessory). 2. Temperature control accuracy of in-situ high-temperature accessories: usually ± 0.5 ℃ (such as in-situ high-temperature accessories), and the accuracy of some equipment above 1000 ℃ is ± 0.5 ℃. 3. Window materials and cooling methods for in-situ high-temperature attachments Window material: Polyester film (temperature resistant to 400 ℃) or beryllium sheet (thickness 0.1mm), used for X-ray penetration. Cooling method: Deionized water circulation cooling ensures stable operation of the equipment under high temperature conditions. 4. Atmosphere and pressure control of in-situ high-temperature attachments: Supports inert gases (such as Ar, N ₂), vacuum or atmospheric environments, and some models can withstand pressures less than 10 bar. The atmosphere gas flow rate can be adjusted (0.7-2.5L/min), suitable for corrosive gas environments. 二、 Application scenarios of in-situ high-temperature attachments 1. Material research on in-situ high-temperature attachments Analyze the changes in crystal structure (such as platinum phase transition) and phase transition processes (such as melting and sublimation) at high temperatures. Study the chemical reactions of materials at high temperatures, such as dissolution and oxidation. 2. Equipment adaptability of in-situ high-temperature attachments Mainly used in X-ray diffractometers (XRD), such as TD-3500, TD-3700, etc. It can also be used for in-situ tensile testing using scanning electron microscopy (SEM), with customized flange connections required. 三、 Precautions for using in-situ high-temperature accessories 1. Sample requirements for in-situ high-temperature attachments It is necessary to test the chemical stability of the sample in the target temperature range in advance to avoid decomposition into strong acids/bases or ceramic bonding. The sample shape must meet the requirements of the attachment (such as thickness 0.5-4.5mm, diameter 20mm). 2. Experimental operating procedures for in-situ high-temperature attachments The heating rate needs to be controlled (e.g. maximum 200 ℃)/ min@100 ℃) to avoid overheating and damaging the equipment. After the experiment, the sample needs to be cooled to room temperature to prevent structural damage.

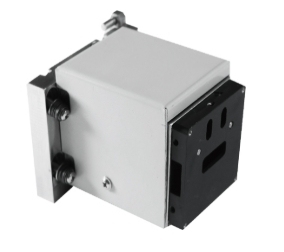

The multifunctional sample stage is a highly integrated experimental equipment mainly used in the fields of materials science, semiconductor manufacturing, electron microscopy analysis, etc. Its core features are modular design, multifunctional integration, and high-precision control. 一、 The core functions and structural characteristics of the multifunctional sample stage 1. Modular design of multifunctional sample stage: Multiple functions are achieved through different module combinations, such as self rotation coupling module (speed 0~20 revolutions per minute, with zero limit), lifting module (standard stroke 50mm/100mm, customizable), heater module (maximum temperature up to 1100 ℃), etc. Support DC/RF power supply connection to meet the needs of thin film growth, sample cleaning, or auxiliary film formation. 2. High precision control and sensors for multifunctional sample stage: Equipped with temperature, pressure and other sensors, real-time monitoring of sample environmental parameters, and adjusting heating, cooling and other operations through the control system. Some models integrate pneumatic baffle modules for easy operation. 3. Compatibility and adaptability of multifunctional sample stage: Suitable for testing irregular samples such as trace powders, sheet materials, and large-sized samples, avoiding the damage caused by traditional cutting or grinding. Supports sample sizes below 6 inches and customizable flange interfaces. 二、 Application Fields of Multi functional Sample Stand 1. Thin film technology for multifunctional sample stage: used for advanced thin film growth technologies such as MBE (molecular beam epitaxy), PLD (pulsed laser deposition), magnetron sputtering, as well as substrate annealing, high-temperature degassing and other processes. 2. Electron microscopy analysis of multifunctional sample stage: Cold field scanning electron microscope: Fix the sample with long screws and adjust the conductivity with compatible brass washers. TEM/FIB system: integrates in-situ delamination, nanoprobe testing, and TEM analysis to avoid contamination or damage caused by sample transfer. 3. Failure analysis of multifunctional sample stage: Integrating atomic site stripping, electrical testing and analysis processes in FIB and TEM systems to improve success rate and efficiency. 三、 Technical advantages of multifunctional sample stage 1. Integration and automation of multifunctional sample stage: reduces manual operation complexity through modular design, supports overall movement and precise positioning in vacuum environment. 2. High reliability of the multifunctional sample stage: using standard flange interfaces (such as CF50/CF40) to ensure sealing and compatibility. 3. Customization of multifunctional sample table: Heating material, stroke length, and sample holder type (such as 3-jaw bayonet type, bottom fork type) can be selected according to needs. Overall, the multifunctional sample stage is a key equipment for material research and micro analysis, commonly used in X-ray diffraction instruments. Its value lies in functional integration, operational flexibility, and adaptability to complex experimental requirements. The specific selection needs to match the corresponding modules and performance parameters according to the actual application scenarios (such as thin film technology, electron microscopy analysis, or failure analysis).

一、Core functions and application scenarios of originally battery accessories Functional positioning of originally battery accessories: 1.Implement real-time testing during battery charging and discharging processes (such as XRD, optical observation, etc.) to avoid data loss or sample contamination caused by traditional disassembly. 2.Simulate the working environment of real batteries, support temperature control, electrolyte addition, and sealing guarantee. Typical application scenarios of originally battery accessories: 1.XRD in-situ testing: Analyze the crystal phase changes of electrode materials (such as LiFePO4) during charge and discharge processes. 2.Optical in-situ observation: Observe the surface reaction of the electrode through a beryllium window (polyester film). 3.High throughput screening: supports battery performance research under multiple conditions (temperature, pressure, electrolyte). 4.Widely used in electrochemical systems containing carbon, oxygen, nitrogen sulfur, metal embedded complexes, etc. 二、Structural composition and material properties of originally battery accessories 1.Core components of originally battery accessories: Lower insulation cover: mostly made of alumina ceramic or polytetrafluoroethylene material, including installation chamber and coolant flow channel, supporting temperature control. Upper conductive cover: designed with through holes, bolted to the lower insulating cover to form a current path. Lower electrode: including top plate and support column, fixed by butterfly spring compression, simplifying the assembly process. Beryllium window (polyester film): diameter 15mm (customizable), thickness 0.1mm (customizable), used for X-ray penetration or optical observation. 2.Technical improvement of originally battery accessories: Formal assembly: replaces traditional inverted methods, simplifies the operation process, and reduces the impact of compression on the separator and positive electrode materials. Cooling and Heating: The lower insulation cover integrates a coolant channel or resistance wire pipeline, supporting temperature control of -400℃. Sealing design: The butterfly spring compresses and fixes the lower electrode, and cooperates with the installation seat airflow to blow and prevent frost and ice formation. 三、Technical advantages of originally battery accessories 1. Convenient operation of originally battery accessories: The formal structure reduces the operating time inside the glove box and lowers the assembly complexity. Modular design of components (such as replaceable beryllium windows and insulation sleeves) improves maintenance efficiency. 2. Performance parameters: Test range: Temperature range of 0.5-160℃, temperature resistance up to 400 ℃. Sealing: Supports long-term stable storage of electrolyte to avoid leakage. Compatibility: Suitable for X-ray diffractometers and other equipment.

XRD and FTIR fiber accessories provide complete material characterization solutions. XRD units analyze crystal structure and orientation, while FTIR systems identify composition through micro-imaging and ATR technology. Accessories include small-angle diffraction, parallel beam thin-film, and in-situ temperature stages for nanoscale analysis. Automated sample handling enhances efficiency. Applications span material research, industrial quality control, and scientific studies of polymer dichroism. These tools continue to evolve, driving innovations in fiber science and industrial applications.

Multifunctional Integrated Measurement Attachment enables precise texture, stress and thin-film analysis. Supports pole figure mapping, biaxial stress measurement and in-plane rotation. Ideal for metals, ceramics, coatings and polymers. Features 0.001° step precision and Φ100mm sample capacity.