- Home

- >

News

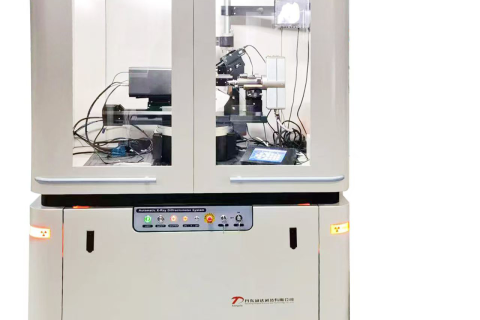

X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic,organic,and metal complexes,and to analyze the structure of special materials such as twinning, non commensurate crystals,quasicrystals,etc.Determine the accurate three-dimensional space (including bond length, bond angle,configuration,conformation,and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice;Single crystal X-ray diffractometer can provide information on the crystal cell parameters,space group,molecular structure,intermolecular hydrogen bonding and weak interactions,as well as structural information such as molecular configuration and conformation.Single crystal XRD is widely used in analytical research in chemical crystallography,molecular biology,pharmacology,mineralogy,and materials science. Single crystal XRD has high precision: 2θ angle repeatability accuracy: 0.0001°; Minimum step angle: 0.0001°; Temperature control range:100K-300K Control accuracy: ±0.3K Single crystal angle measuring instrument selects four concentric scanning circles. Single crystal XRD adopts low-temperature configuration. The company's technical personnel have completed the installation and debugging of the foreign single crystal X-ray diffractometer,and the test results have greatly satisfied foreign users. At the same time,the functionality,stability,and after-sales service of the instrument have received unanimous praise from foreign users. Overall, X-ray single crystal diffractometer plays an irreplaceable role as an important scientific instrument in research and application in multiple disciplines. With the continuous advancement and innovation of technology, we believe that in the future,single crystal XRD will demonstrate their unique value and potential in more fields.

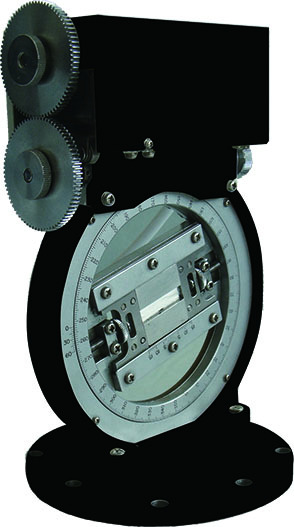

The TDF series X-ray crystal analyzer is a large-scale X-ray instrument used to study the internal microstructure of substances. It utilizes the principle of interaction between X-ray and crystal to determine the atomic arrangement inside the crystal by analyzing the diffraction pattern of X-ray. Mainly used for single crystal orientation, defect inspection, determination of lattice parameters, determination of residual stress, study of the structure of plate and rod, investigation of the structure of unknown substances and single crystal dislocations. The X-ray crystal analyzer, as an X-ray instrument, provides valuable information for materials science research and other related fields. With the continuous advancement of technology and the expansion of applications, X-ray crystal analyzer will continue to play an important role in scientific research and industrial production.

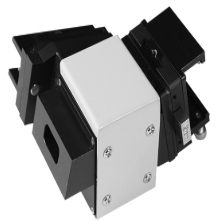

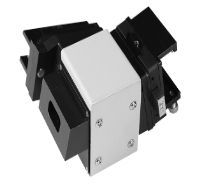

The Graphite curved crystal monochromator is an important instrument accessory for X-ray diffraction analysis, mainly used to monochromatize the X-rays passing through the receiving slit, thereby improving the accuracy and signal-to-noise ratio of analysis. This monochromator utilizes the specific structure of graphite crystals to selectively reflect incident X-rays, allowing only X-rays of specific wavelengths (usually Kαcharacteristic X-rays) to pass through while filtering out other unwanted X-ray components such as continuous X-rays, Kβcharacteristic X-rays, and fluorescent X-rays. This selective reflection is based on Bragg's law, which states that when the angle between the incident light and the crystal plane satisfies certain conditions, coherent scattering occurs, forming diffraction peaks.When using this monochromator, attention should be paid to the preparation and placement of the sample to ensure the accuracy and symmetry of the diffraction peaks. Graphite curved crystal monochromator are widely used in materials research fields such as chemistry, chemical engineering, machinery, geology, minerals, metallurgy, building materials, ceramics, petrochemicals, and pharmaceuticals. In these fields, it is used for X-ray diffraction analysis to study the physical properties of materials such as crystal structure, phase transition, stress state, etc.X-ray diffractometer accessories significantly improves the accuracy and reliability of analysis by increasing the peak to background ratio and reducing background noise.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber crystallinity and half peak width. Fiber accessories have a wide range of applications in various fields, including materials science, biomedicine, chemical engineering, nanotechnology, geological exploration, environmental monitoring, and more.

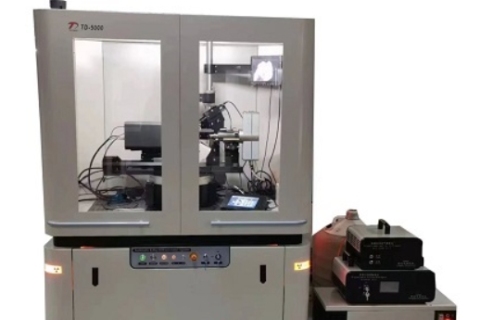

The TD-5000 X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; Single crystal X-ray diffractometer can provide information on crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation. Single crystal XRD is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science. The single crystal diffractometer adopts the four circle concentricity technique to ensure that the center of the angle measuring instrument remains unchanged regardless of the rotation, achieving the goal of obtaining the most accurate data and obtaining higher integrity. Four circle concentricity is a necessary condition for conventional single crystal scanning. The company's technical personnel have completed the installation and debugging of the foreign single crystal X-ray diffractometer, and the test results have greatly satisfied foreign users. At the same time, the functionality, stability, and after-sales service of the instrument have received unanimous praise from foreign users.

A high-precision X-ray single crystal diffractometer designed specifically for materials science research, crystal structure analysis, and industrial quality control. It utilizes the diffraction effect generated by the interaction between X-rays and single crystals to provide users with detailed crystal structure information by accurately measuring diffraction angles and intensities, thereby revealing the microstructure and properties of materials.

A monochromator is a component installed in front of an X-ray detector, which monochromatizes the X-rays passing through a receiving slit and only detects K α characteristic X-rays in the X-ray spectrum. By using this device, continuous X-rays, K β characteristic X-rays, and fluorescent X-rays can be completely eliminated, enabling high signal-to-noise ratio X-ray diffraction analysis. When copper target X-ray tubes are used in conjunction with corresponding monochromators, fluorescent X-rays generated from Mn, Fe, Co, Ni based samples can be eliminated, making them suitable for analysis of various samples. The use of graphite bent crystal monochromator can improve the peak to background ratio, reduce the background, enhance the resolution of weak peaks, achieve a reflection efficiency of n ≥ 35%, and reduce the diffraction angle of the diffractometer. Embedding degree ≤ 0.55; The crystal surface can tilt ± 2 degrees.

The in-situ battery accessory is a component of the X-ray diffractometer accessories.In situ battery accessories are widely used in electrochemical systems containing composite materials such as carbon, oxygen, nitrogen sulfur, and metal inserts. Test range: 0.5-160 degrees Celsius Temperature resistance: 400 ℃ Beryllium window (polyester film) size: diameter 15mm (customizable); Thickness 0.1mm (customizable) Dandong Tongda Technology Co., Ltd. is a professional manufacturer of X-ray diffractometers、Wholesaler of X-ray directional analyzer、Wholesaler of X-series X-ray crystal analyzer。

Using X-ray diffraction (transmission) method to test the unique crystal structure of fibers. Test the orientation of the sample based on data such as fiber texture and half peak width.

Dandong Tongda Technology Co., Ltd. is a professional manufacturer of X-ray products, with two main series of products: X-ray analysis instruments and X-ray non-destructive testing instruments. And in 2013, it became the undertaking unit of the X-ray single crystal diffractometer project of the National Major Scientific Instrument and Equipment Development Special Project of the Ministry of Science and Technology. Our company adheres to the principles of customer first, product first, and service first, insists on people-oriented, and has a strong technology team. We are committed to providing users with the highest quality high-tech products with advanced technology, and providing strong support and services to users with efficient technical consulting and after-sales service institutions.

The data collected through low-temperature equipment yields more ideal results. With the help of low-temperature equipment, more advantageous conditions can be provided, which can enable undesirable crystals to obtain ideal results, as well as ideal crystals to obtain more ideal results.

Dandong Tongda Technology Co., Ltd. is a professional manufacturer of X-ray products, with two main series of products: X-ray analysis instruments and X-ray non-destructive testing instruments. And in 2013, it became the undertaking unit of the national major scientific instrument and equipment development special X-ray single crystal diffractometer project of the Ministry of Science and Technology of China. Our company adheres to the principles of customer first, product first, and service first, insists on people-oriented, and has a strong scientific and technological team. We are committed to providing users with the highest quality high-tech products with advanced technology, and providing strong support and services with efficient technical consulting and after-sales service institutions.