- Home

- >

News

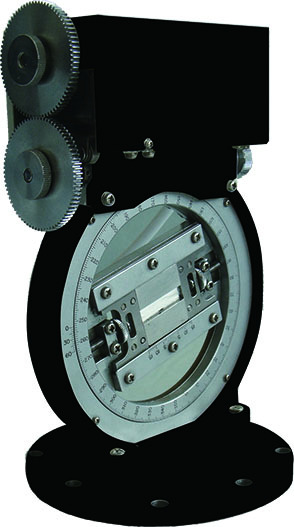

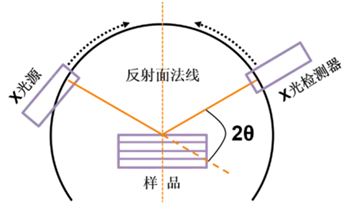

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber texture and half peak width.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on the fiber crystallinity and half peak width of the fibers. This type of accessory is usually installed on a wide-angle diffractometer and is mainly used to study the texture of thin films on the substrate, perform crystal phase detection, orientation, stress testing, and other tests.

Parallel optical film measuring accessory is a specialized tool for X-ray diffraction analysis, which filters out more scattered lines by increasing the length of the grating plate, thereby reducing the influence of the substrate signal on the results and enhancing the signal intensity of the thin film. In the field of materials science, parallel optical film measuring accessory is commonly used to study the crystal structure, phase transition behavior, and stress state of thin film materials. With the development of nanotechnology, parallel optical film measuring accessory has also been widely used in thickness testing and small angle diffraction analysis of nano multilayer films. The design and manufacturing of parallel optical film measuring accessory pursue high precision to meet the requirements of scientific research and industrial production for data accuracy. During use, parallel optical film measuring accessory need to maintain a high degree of stability to ensure the reliability of test results. With the advancement of technology and the development of industry, the demand for high-precision and high stability analytical instruments is constantly increasing. Parallel optical film measuring accessory, as an important component, are also experiencing sustained market demand growth. In order to meet market demand and improve product performance, the technology of parallel optical film measuring accessory is constantly innovating and improving. For example, improving the material and design of grating plates, optimizing the optical system, and other means can enhance the filtering effect and signal enhancement capability. In summary, parallel optical film measuring accessory play a crucial role in X-ray diffraction analysis. With the advancement of technology and the development of industry, its application prospects will become even broader.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber crystallinity and half peak width. Fiber accessories have a wide range of applications in various fields, including materials science, biomedicine, chemical engineering, nanotechnology, geological exploration, environmental monitoring, and more.

Using X-ray diffraction (transmission) method to test the unique crystal structure of fibers. Test the orientation of the sample based on data such as fiber texture and half peak width.

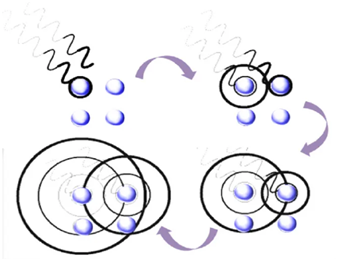

The use of hybrid pixel detector can achieve the best data quality while ensuring low power consumption and low cooling. This detector combines the key technologies of single photon counting and hybrid pixels, and is applied in various fields such as synchrotron radiation and conventional laboratory light sources, effectively eliminating the interference of readout noise and dark current. Hybrid pixel technology can directly detect X-rays, making it easier to distinguish signals, and detector can efficiently provide high-quality data.

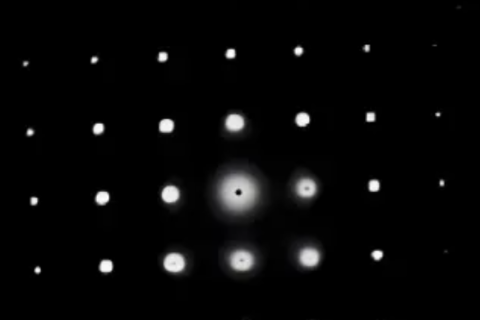

The X-ray diffraction pattern serves as the most reliable foundation for determining polycrystalline patterns, and the X-ray diffraction pattern is frequently regarded as the "fingerprint" of crystalline patterns.

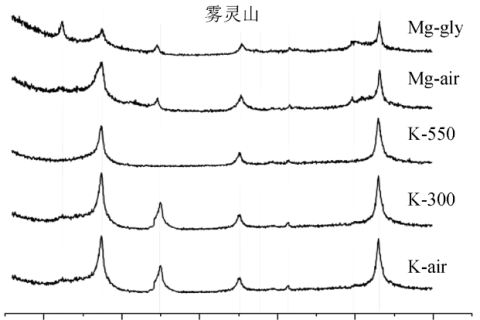

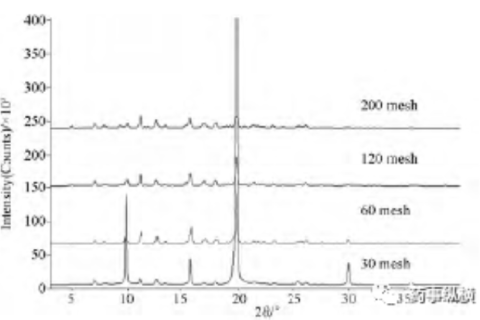

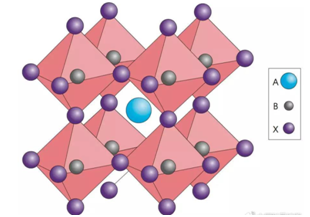

The crystal structure of the perovskite films modified by ionic liquid (ILs) BMIMAc under various annealing durations was characterized by X-ray diffraction.

X-ray diffraction is a fast, accurate and efficient non-destructive testing technique for materials. As a means of characterizing the crystal structure and its change rule, it is widely used in many fields such as biology, medicine, ceramics and so on.