- Home

- >

News

The TDM-10 desktop x ray diffraction instrumentation is an instrument used for analyzing the phase structure of materials, which can be equipped with scintillation/proportional/linear array detectors. 1. The working principle of TDM-10 desktop x ray diffraction instrumentation:Based on Bragg's law, when a monochromatic X-ray beam is incident on a crystal, if the Bragg diffraction condition is satisfied (n λ=2dsin θ, where λ is the wavelength of the X-ray, d is the interplanar spacing, and θ is the incident angle), atoms or molecules in the crystal will scatter and interfere with the X-ray, forming a specific diffraction pattern. By measuring the diffraction intensity at different angles, the structural information of the crystal can be obtained. 2. Characteristics of TDM-10 desktop x ray diffraction instrumentation: The high resolution of a desktop x ray diffraction instrumentation enables precise measurement of the crystal structure of substances, which is crucial for studying complex mixtures or searching for low content polycrystalline and trace phases. Non destructive analysis of desktop x ray diffraction instrumentation: During the testing process, it will not cause damage to the sample, and the sample can remain in its original state for further testing or use. The operation of desktop X-ray powder diffraction equipment is simple: Modern desktop X-ray powder diffraction equipment usually have automation and intelligence functions, making the operation more convenient and reducing the requirements for the operator's professional knowledge and skills. The versatility of desktop X-ray powder diffraction equipment: X-ray powder diffraction equipment can perform various analyses such as phase qualitative and quantitative analysis, lattice constant analysis, stress analysis, etc. 3. Technical parameters of TDM-10 desktop X-ray powder diffraction equipment: Desktop x ray diffraction machine has a small volume; High frequency and high voltage power supply reduces the overall power consumption of the machine; Can quickly calibrate and test samples; Simple circuit control, easy to debug and install; The measurement accuracy of diffraction peak position is 0.001 °; Detector: scintillation, proportional, linear array; Range of 2 θ:- 10°~150° Power: 600W; Maximum voltage: 40kV; Maximum current: 15mA; X-ray tubes: corrugated ceramic tubes, metal ceramic tubes, glass tubes. 4. Application areas of TDM-10 desktop x ray diffraction machine: Materials Science: Used to study the crystal structure, phase composition, grain size, crystallinity, etc. of metals, ceramics, semiconductors, and other materials, helping materials scientists understand the properties and characteristics of materials. In the field of chemistry, x ray diffraction machine can be used in the manufacturing industry of catalysts, cement, pharmaceuticals, and other products to identify phases in unknown samples, as well as to quantitatively analyze known phases in mixed samples. Geology: Conducting phase analysis on ores, rocks, etc. to determine their mineral composition and structure. Environmental science: used to analyze the mineral composition and pollutant forms in environmental samples such as soil and sediment. Food industry: detecting crystal components, additives, etc. in food. The TDM-10 desktop x ray diffraction machine is a powerful analytical instrument with important application value in multiple fields.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber texture and half peak width.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on the fiber crystallinity and half peak width of the fibers. This type of accessory is usually installed on a wide-angle diffractometer and is mainly used to study the texture of thin films on the substrate, perform crystal phase detection, orientation, stress testing, and other tests.

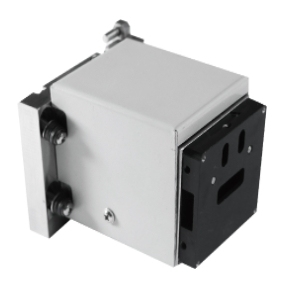

Parallel optical film measuring accessory is a specialized tool for X-ray diffraction analysis, which filters out more scattered lines by increasing the length of the grating plate, thereby reducing the influence of the substrate signal on the results and enhancing the signal intensity of the thin film. In the field of materials science, parallel optical film measuring accessory is commonly used to study the crystal structure, phase transition behavior, and stress state of thin film materials. With the development of nanotechnology, parallel optical film measuring accessory has also been widely used in thickness testing and small angle diffraction analysis of nano multilayer films. The design and manufacturing of parallel optical film measuring accessory pursue high precision to meet the requirements of scientific research and industrial production for data accuracy. During use, parallel optical film measuring accessory need to maintain a high degree of stability to ensure the reliability of test results. With the advancement of technology and the development of industry, the demand for high-precision and high stability analytical instruments is constantly increasing. Parallel optical film measuring accessory, as an important component, are also experiencing sustained market demand growth. In order to meet market demand and improve product performance, the technology of parallel optical film measuring accessory is constantly innovating and improving. For example, improving the material and design of grating plates, optimizing the optical system, and other means can enhance the filtering effect and signal enhancement capability. In summary, parallel optical film measuring accessory play a crucial role in X-ray diffraction analysis. With the advancement of technology and the development of industry, its application prospects will become even broader.

The small angle diffractometer accessories are special device used in X-ray diffraction (XRD) experiments, mainly for measuring diffraction peaks in the low angle range to study the microstructure and properties of materials. The small angle diffractometer accessories are specialized device for X-ray diffractometers that allows for precise diffraction measurements within a lower 2θangle range (typically from 0°to 5°or lower). This technology is of great significance for studying nanostructures, mesoporous materials, multilayer films, and other materials. By configuring corresponding small angle diffractometer accessories, the thickness of nano multilayer films can be accurately measured. Overall, small angle diffractometer accessories are an indispensable and important component of X-ray diffractometers, with broad application prospects in materials science, chemistry, physics, and other fields.

Fiber accessories are tested for their unique crystal structure using X-ray diffraction (transmission) method. Test the orientation of the sample based on data such as fiber crystallinity and half peak width. Fiber accessories have a wide range of applications in various fields, including materials science, biomedicine, chemical engineering, nanotechnology, geological exploration, environmental monitoring, and more.

The TD-3700 high-resolution X-ray diffractometer, with all the advantages of the TD-3500 X-ray diffractometer, is equipped with a high-performance array detector. Compared to scintillation detectors or proportional detectors, diffraction calculation intensity can be increased by several tens of times, and complete high-sensitivity, high-resolution diffraction patterns and higher counting intensity can be obtained in a shorter sampling period. The TD-3700 high-resolution X-ray diffractometer supports both conventional diffraction data scanning and transmission data scanning methods. The resolution of transmission mode is much higher than that of diffraction mode, which is suitable for structural analysis and other fields. Diffraction mode has strong diffraction signals and is more suitable for routine phase identification in the laboratory. In addition, in the transmission mode, the powder sample can be in trace amounts, which is suitable for data acquisition in cases where the sample size is relatively small and does not meet the requirements of diffraction method for sample preparation.

Using X-ray diffraction (transmission) method to test the unique crystal structure of fibers. Test the orientation of the sample based on data such as fiber texture and half peak width.

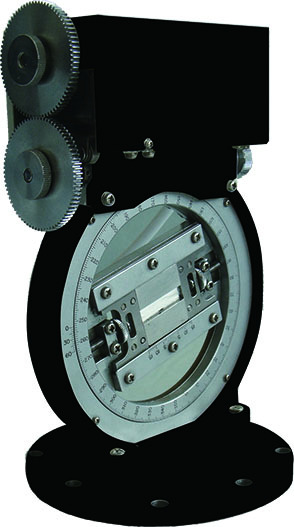

The use of four concentric circles technique ensures that the center of the angle measuring instrument remains unchanged regardless of any rotation, achieving the goal of obtaining the most accurate data and higher completeness. Four concentric circles are a necessary condition for conventional single crystal scanning.

X-ray diffractometer is mainly used for phase qualitative and quantitative analysis, crystal structure analysis, material structure analysis, crystal orientation analysis, macroscopic or microscopic stress determination, grain size determination, crystallinity determination, etc. of powder, block or film samples.

The use of hybrid pixel detector can achieve the best data quality while ensuring low power consumption and low cooling. This detector combines the key technologies of single photon counting and hybrid pixels, and is applied in various fields such as synchrotron radiation and conventional laboratory light sources, effectively eliminating the interference of readout noise and dark current. Hybrid pixel technology can directly detect X-rays, making it easier to distinguish signals, and detector can efficiently provide high-quality data.

The high-precision multifunctional angle measuring instrument of Tongda Technology can not only measure conventional powder samples, but also test liquid samples, colloidal samples, viscous samples, loose powders, and large solid samples.