X-ray diffraction characterization of polymers

2023-12-04 10:00Polymer conventional X-ray diffraction

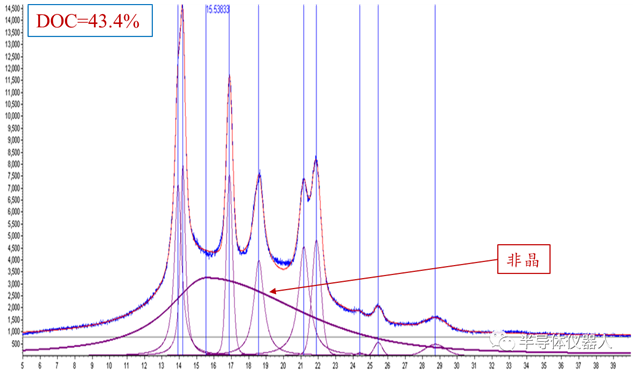

Conventional X-rays are often used to characterize polymer crystallinity or material equality information. The crystallinity of polymer is a structural parameter closely related to its physical properties. Sometimes, it is possible to determine the cause of insufficient stiffness, cracks, whiteness, and other defects by evaluating crystallinity. The method of measuring crystallinity by X-ray diffraction and full spectrum fitting is described and some examples are given.

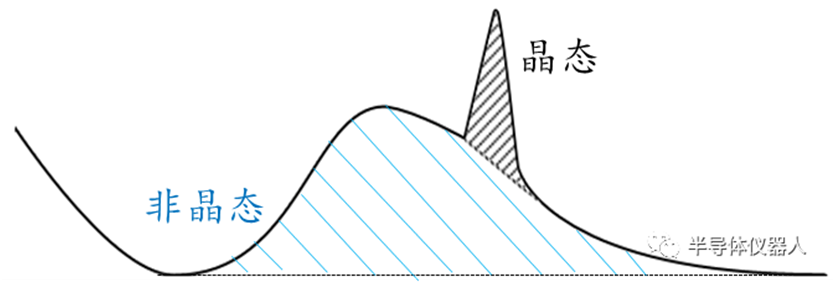

Ratio of crystalline diffraction peak area to total scattered signal area

The XRD pattern of PP-PP and the results of calculating crystallinity by separating crystalline and amorphous peaks by full spectrum fitting method

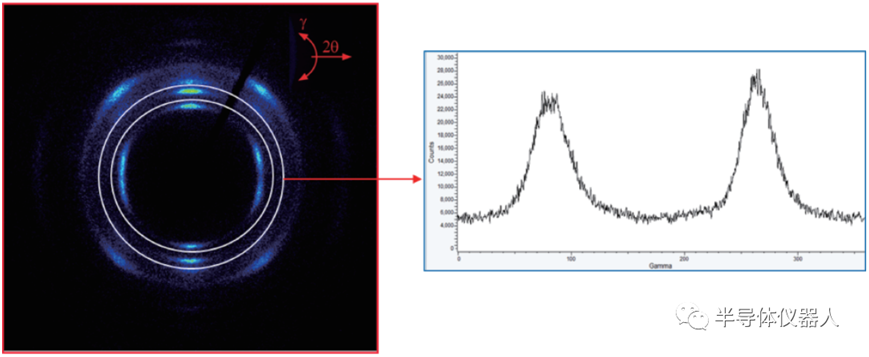

Polymer 2D/ X-ray diffraction

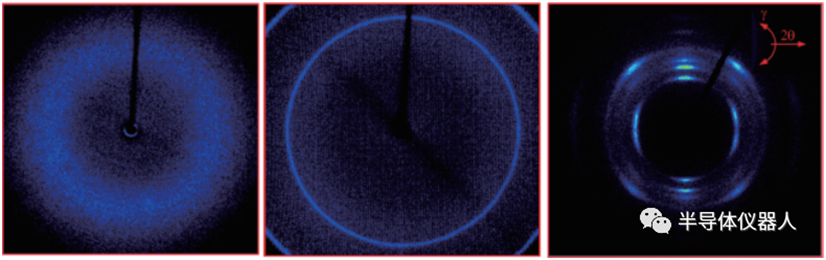

For polymer materials, they are added into fibers, sheets, or other shapes. The difference in processing method or processing technology will lead to a great difference in its crystallization state and orientation. The conventional X-ray diffraction test can not characterize all the structural features. The 2D detector (XRD) transmission mode provides intuitive and comprehensive structural information about polymer materials. In the following, PP samples of different states were tested by two-dimensional X-ray diffractometer, which fully demonstrated the advantages of two-dimensional diffraction in polymer analysis.

![]()

Two-dimensional X-ray map of PP sample PP1#- amorphous state PP2#- non-oriented semi-crystalline state

Orientation analysis

The (040) peaks of PP3# samples only exist in two directions in the two-dimensional map. By integrating the (040) peak of the sample with 2theta, the azimuth diagram of the (040) peak intensity can be obtained, and the orientation can be further calculated by using the half-height and width of the peak of the azimuth diagram.