- Home

- >

News

Dandong Tongda's X-ray non-destructive testing equipment ensures precise internal inspection for aerospace, automotive and construction sectors. Featuring portable design and advanced safety systems, it delivers reliable defect detection while maintaining complete operational safety.

X-ray irradiator is a scientific research equipment that uses X-rays to irradiate biological samples, materials, or small animals, and is widely used in fields such as biology, medicine, and materials science. 1. Core functions and technical principles of X-ray irradiation equipment (1) Functional positioning Biological research: used for DNA damage, cell mutagenesis, stem cell differentiation induction, tumor mechanism research, immunology and gene therapy experiments, etc. Medical applications: radiation disinfection, blood product processing, analysis of tumor cell apoptosis, pre-treatment for organ transplantation, etc. Materials and Environmental Science: Nanomaterial Modification, Food Radiation Quarantine, Soil Pollutant Analysis, etc. (2) Technical principles By accelerating electrons with high voltage to collide with metal targets, X-rays are generated; After optimization through filters, beam limiting devices, etc., the sample is irradiated to achieve targeted intervention by precisely controlling the dose rate, irradiation time, and range. 2. Key technical parameters of X-ray irradiation equipment (1) Radiation performance Tube voltage: 30-225kV (different models vary). Dose rate: 0.1-16Gy/minute, supporting precise and stepless adjustment. Dose uniformity: ≥ 95% (industry-leading level). Radiation angle and coverage area: The maximum radiation angle is 40 degrees, and the coverage diameter is up to 30cm. (2) Operation and Safety Design Intelligent control: touch screen operation interface, data export function (compatible with Excel). Safety protection: lead shielded cabinet, environmental dose<20 μ R/h (5cm away from equipment), multiple interlocks and fault alarms. Cooling system: Closed loop cooling technology extends the lifespan of X-ray tubes (up to 2000 hours). (3) Applicable sample types Cells, tissue organs, bacteria, mice, rats, etc., support irradiation of small animals in a conscious or anesthetized state. 3.Typical products and manufacturers of X-ray irradiation equipment Domestic representative: Dandong Tongda Technology Co., Ltd Advantages: Localization reduces procurement costs, simplifies operations (without the need for complex X-ray knowledge), and meets national safety standards. 4. Expansion of application fields for X-ray irradiation equipment (1) Biology and Medicine Cell research: inducing gene mutations, cell cycle regulation, signal transduction analysis. Tumor research: irradiation of tumor cell models to explore apoptosis mechanisms or radiation sensitivity. Preclinical studies: Whole body irradiation of small animals (such as mice) for research on hematopoietic system, immune response, etc. (2) Materials and Environmental Science Nanomaterial modification: changing the crystal structure or surface properties of materials through irradiation. Food quarantine: Non destructive detection of foreign objects, residual preservatives, or microbial inactivation. Nuclear waste disposal: Assist in analyzing the distribution of radioactive materials to ensure safe disposal. (3) Agriculture and Breeding Mutation breeding: Irradiating plant seeds or insects to accelerate gene mutations and screen for superior traits. 5. Development trends and challenges of X-ray irradiation equipment (1) Technical upgrade direction Intelligence: Combining AI algorithms to optimize dose distribution and experimental design. Safety: Reduce environmental radiation leakage and improve protection standards. Multi functional integration: such as integrating CT imaging and irradiation functions to achieve "detection processing" integration. (2) Industry challenges High precision dose control and stability require continuous optimization. More basic data is needed to support the differences in radiation sensitivity among biological samples. Overall, X-ray irradiation equipment is an indispensable tool in scientific research and industry. The X-ray irradiation equipment produced by Dandong Tongda Technology Co., Ltd. achieves a balance between performance and cost and is widely used in multiple fields. In the future, with technological iteration, its application scope will further expand to cutting-edge directions such as precision medicine and new material research and development.

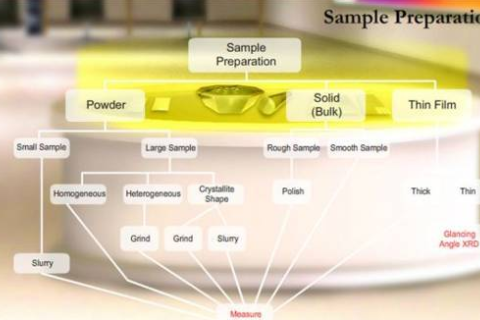

The TDM-10 desktop x ray diffraction instrumentation is an instrument used for analyzing the phase structure of materials, which can be equipped with scintillation/proportional/linear array detectors. 1. The working principle of TDM-10 desktop x ray diffraction instrumentation:Based on Bragg's law, when a monochromatic X-ray beam is incident on a crystal, if the Bragg diffraction condition is satisfied (n λ=2dsin θ, where λ is the wavelength of the X-ray, d is the interplanar spacing, and θ is the incident angle), atoms or molecules in the crystal will scatter and interfere with the X-ray, forming a specific diffraction pattern. By measuring the diffraction intensity at different angles, the structural information of the crystal can be obtained. 2. Characteristics of TDM-10 desktop x ray diffraction instrumentation: The high resolution of a desktop x ray diffraction instrumentation enables precise measurement of the crystal structure of substances, which is crucial for studying complex mixtures or searching for low content polycrystalline and trace phases. Non destructive analysis of desktop x ray diffraction instrumentation: During the testing process, it will not cause damage to the sample, and the sample can remain in its original state for further testing or use. The operation of desktop X-ray powder diffraction equipment is simple: Modern desktop X-ray powder diffraction equipment usually have automation and intelligence functions, making the operation more convenient and reducing the requirements for the operator's professional knowledge and skills. The versatility of desktop X-ray powder diffraction equipment: X-ray powder diffraction equipment can perform various analyses such as phase qualitative and quantitative analysis, lattice constant analysis, stress analysis, etc. 3. Technical parameters of TDM-10 desktop X-ray powder diffraction equipment: Desktop x ray diffraction machine has a small volume; High frequency and high voltage power supply reduces the overall power consumption of the machine; Can quickly calibrate and test samples; Simple circuit control, easy to debug and install; The measurement accuracy of diffraction peak position is 0.001 °; Detector: scintillation, proportional, linear array; Range of 2 θ:- 10°~150° Power: 600W; Maximum voltage: 40kV; Maximum current: 15mA; X-ray tubes: corrugated ceramic tubes, metal ceramic tubes, glass tubes. 4. Application areas of TDM-10 desktop x ray diffraction machine: Materials Science: Used to study the crystal structure, phase composition, grain size, crystallinity, etc. of metals, ceramics, semiconductors, and other materials, helping materials scientists understand the properties and characteristics of materials. In the field of chemistry, x ray diffraction machine can be used in the manufacturing industry of catalysts, cement, pharmaceuticals, and other products to identify phases in unknown samples, as well as to quantitatively analyze known phases in mixed samples. Geology: Conducting phase analysis on ores, rocks, etc. to determine their mineral composition and structure. Environmental science: used to analyze the mineral composition and pollutant forms in environmental samples such as soil and sediment. Food industry: detecting crystal components, additives, etc. in food. The TDM-10 desktop x ray diffraction machine is a powerful analytical instrument with important application value in multiple fields.

NDT portable X-ray welding testing machine is a type of radiographic inspection equipment that can generate X-rays and has multiple uses. Portable X-ray machine for weld inspection can be used in industrial and medical fields. In industry, it is used for defect detection in automotive parts manufacturing, wheel hub detection, subframe detection, hinge quality detection, etc., to ensure that the tested industrial products have high strength. In addition, its belongs to X-ray weld inspection equipment and is commonly used for weld detection, boiler weld detection, aerospace component weld detection, etc.

The NDT non-destructive testing instrument is a small X-ray generator with an anode grounded and forced cooling by a fan; Dandong Tongda Technology's customized wholesale non-destructive testing instruments are lightweight, easy to carry, and easy to operate; Portable welding seam X-ray machine non-destructive testing instrument works and rests in a 1:1 ratio; Radiographic testing equipment: aesthetically pleasing and structurally sound; NDT non-destructive testing instruments are: delayed exposure to ensure operator safety; The main purpose of NDT non-destructive testing equipment is to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers,aircraft,vehicles, and bridges in industrial sectors such as national defense,shipbuilding, petroleum,chemical,mechanical,aerospace,and construction,as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc.

Today, diffractometer has become an important tool in scientific research, education, medical and other fields. However, the precision and complexity of the diffractometer makes it necessary to take extra care during transportation and packaging.

The X-ray single crystal diffractometer is mainly used to determine the three-dimensional spatial structure and electron cloud density of crystalline substances such as inorganic, organic, and metal complexes, and to analyze the structure of special materials such as twinning, non commensurate crystals, quasicrystals, etc. Determine the accurate three-dimensional space (including bond length, bond angle, configuration, conformation, and even bonding electron density) of new compound (crystalline) molecules and the actual arrangement of molecules in the lattice; It can provide information on the crystal cell parameters, space group, crystal molecular structure, intermolecular hydrogen bonding and weak interactions, as well as structural information such as molecular configuration and conformation. It is widely used in analytical research in chemical crystallography, molecular biology, pharmacology, mineralogy, and materials science.

In the process of drug development, the properties and structure of drug crystal powders play a crucial role in their efficacy and safety, and the application of X-ray diffraction (XRD) technology provides us with a powerful tool.

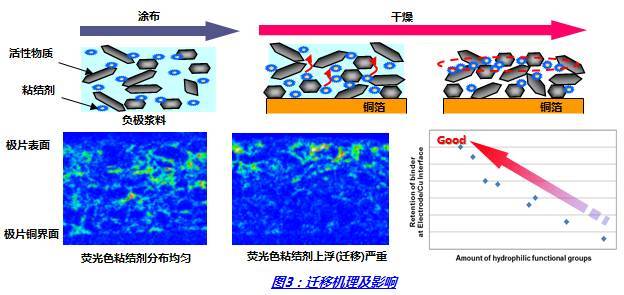

Binder is a polymer compound used in electrode making to adhere the active substance to the collector fluid. The main function is to bond and maintain active substances.

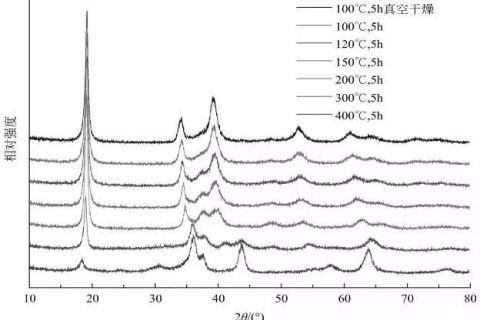

The precursor of ternary material is a low-cost compound of variable valence metal, which will be oxidized in the air, and the higher the drying temperature, the more serious the oxidation degree, and the general choice of air atmosphere drying.

X-ray testing is a non-destructive testing method that does not damage the object itself, and has been widely used in material testing (QC), failure analysis (FA), quality control (QC), quality assurance and reliability (QA/QC), research and development (R&D) and other fields.

Today, let's share some knowledge of X-ray diffractometer operation, mainly in the following aspects.