The key process of ternary material precursor - drying process

2023-10-26 10:00The drying process includes the determination of drying time, drying temperature and drying atmosphere. The precursor of ternary material is a low-cost compound of variable valence metal, which will be oxidized in the air, and the higher the drying temperature, the more serious the oxidation degree. However, due to the high cost and low drying efficiency of vacuum drying and inert atmosphere protection drying, and the quality of the precursor dried out at the appropriate temperature in the air atmosphere can basically meet the requirements, so air atmosphere drying is generally selected.

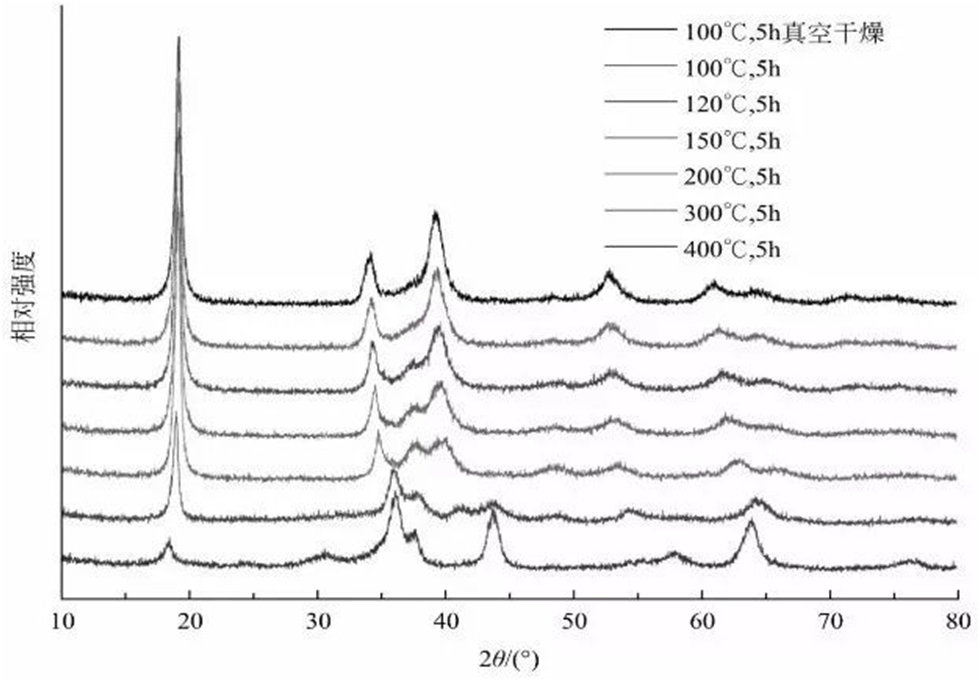

XRD pattern of ternary precursor treated at different drying temperatures

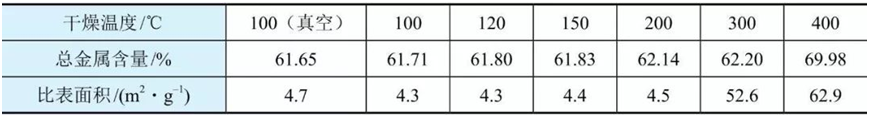

It can be seen from the figure that there is a significant difference between the XRD pattern of the precursor treated at 150℃ and that of the vacuum treated at 100℃, so the drying temperature of the precursor filter cake in the air should be less than 150℃. When the temperature reaches 400 ° C, the precursor is oxidized to a trivalent oxide. At different drying temperatures, the total metal content of the precursor increased with the increase of drying temperature, and the specific surface area increased suddenly after increasing 200℃.

The total metal content and specific surface area of the precursor at different drying temperatures

When it is determined that the drying temperature of the precursor cannot be higher than 150 ° C, the moisture content can be less than 1% according to the drying efficiency of the drying equipment and the precursor moisture control standard, and the drying time required by different drying equipment is different.