Lithium battery negative black spot cause analysis!

2023-10-25 10:001 Negative dark spot phenomenon

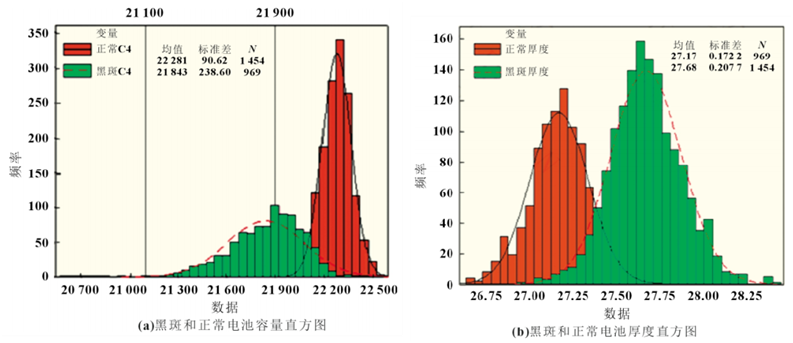

After using the LFP positive electrode and the graphite negative electrode in accordance with the conventional manufacturing process for the first time, it was found that the battery capacity was less than 0.1% to 0.5% of the normal level, and the battery thickness increased by 1.85%.

2. Morphology & composition of negative dark spots

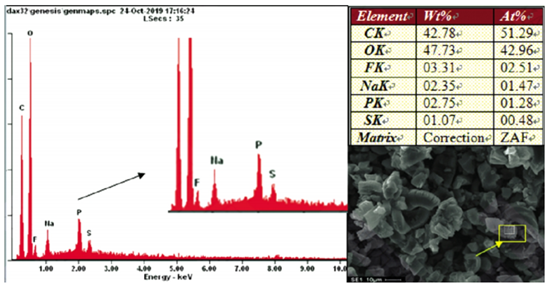

SEM&EDS composition analysis was performed on the black spot position at the end of the polar plate and the normal polar plate. The results showed that the composition of the normal negative electrode plate was 100%C element, and the black spot position also contained 4%-44% O element, 1%-3% F/P element, and 2% Na element at individual points (FIG. 3).

3. Cause analysis of negative dark spots

The structure of negative carbon materials is complex and there are many kinds, and their conductive behavior varies with different electrolytic liquid systems. The chemical or electrochemical reaction of the electrolyte at the negative electrode interface has an important impact on the capacity characteristics and charge-discharge characteristics of the battery. Therefore, the failure analysis of the negative electrode surface should start from the structural characteristics of the carbon negative electrode material, the composition of the electrolytic liquid system, and the matching degree of the reaction between the negative electrode and the electrolyte interface. Moreover, the control of interface reaction and the improvement of battery performance have important guiding effect.

TD-3700 X-ray Diffractometer TD-3500 X-ray Diffractometer