- Home

- >

News

Dandong Tongda Technology provides superior X-ray tubes for analytical instruments. Our specialized tubes (ceramic, metal-ceramic, glass) ensure excellent compatibility with XRD, XRF, and crystal analyzers. Offering diverse target materials, precise focal spots, and robust power outputs (2.4kW/2.7kW). Committed to quality and reliability for global partners in industrial and research applications.

The Diffractometer X-Ray Tube manufactured by Dandong Tongda Technology Co., Ltd. serves as a core component in numerous X-ray analytical instruments within China. Dandong Tongda's Diffractometer X-Ray Tube primarily features the following technical characteristics: Diverse Target Material Options: This X-ray tube offers a variety of target material choices, including Cu, Co, Fe, Cr, Mo, Ti, W, and more. Users can select the most suitable target material based on the elemental composition of the material being tested and the specific analysis requirements, to achieve optimal analytical results. Flexible Focal Spot Configurations: The product provides different focal spot sizes, such as 0.2×12mm, 0.4×14mm (fine focus), and 1×10mm. Smaller focal spot sizes help improve spatial resolution, while the different shape designs meet the optical system requirements of various analytical instruments like XRD and XRF. Wide Power Range: The maximum output power of the X-ray tube covers multiple levels, including 2.0kW, 2.4kW, and 2.7kW, enabling it to adapt to various application scenarios from routine analysis to those requiring high power. Key Technologies and Performance Advanced Generator Technology: The high-frequency, high-voltage generator designed for use with the X-ray tube can achieve a maximum output power of 5kW. It utilizes microcomputer automatic control, with tube voltage adjustment precision up to 1kV per step and tube current adjustment precision up to 1mA per step, ensuring precise and stable output signals. Exceptional Stability Performance: The output stability of the generator is better than 0.01%. The comprehensive stability of some high-end models can even reach ≤0.3%. This high level of stability is crucial for precision analytical work that requires long-term data acquisition. Comprehensive Safety Protection: The equipment is equipped with extensive alarm and protection devices, including multiple protection functions such as over-voltage, over-current, over-power, water shortage, and X-ray tube over-temperature, ensuring safe and reliable operation. Main Application Areas Dandong Tongda's X-ray tubes are primarily used in the following types of analytical instruments: X-Ray Diffractometers (XRD): Used for phase analysis of materials, crystal structure determination, etc. X-Ray Fluorescence Spectrometers (XRF): Used for qualitative and quantitative elemental analysis. Crystal Analyzers and Orienters: Can be used for single crystal orientation, defect inspection, etc.

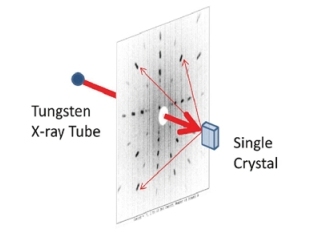

Special corrugated ceramic tubes, metal ceramic tubes, and glass tubes for analytical instruments, suitable for various models of XRD, XRF, crystal analyzers, and orientation instruments at home and abroad. An X-ray tube is a vacuum electronic device that generates X-rays by high-speed electron impact on a metal target material. Its structure, principle, and application involve various technical characteristics. 1. Basic structure of X-ray tube (1) Cathode (electron emission source) Composed of tungsten filament, X-ray tube heats up and emits electrons after being powered on, and is wrapped around a focusing cover (cathode head) to control the direction of the electron beam. The filament temperature is about 2000K, and the electron emission is regulated by current. (2) Anode (target material) Usually high melting point metals (such as tungsten, molybdenum, rhodium, etc.) are used to withstand high-energy electron bombardment and generate X-rays. Contains anode head (target surface), anode cap, glass ring, and anode handle, responsible for heat dissipation (through radiation or conduction) and absorption of secondary electrons. (3) Vacuum shell and window Glass or ceramic shell maintains a high vacuum environment (not less than 10 ⁻⁴ Pa) to avoid electron scattering. Window materials require low X-ray absorption, commonly using beryllium sheets, aluminum, or Lindemann glass. 2. Working principle of X-ray tube (1) Electron Acceleration and Impact The electrons emitted by the cathode filament are accelerated by high voltage (in the range of kilovolts to megavolts) and collide with the anode target material. The process of converting electronic kinetic energy into X-rays includes: Bremsstrahlung: Continuous spectrum X-rays released when electrons decelerate or deflect. Characteristic radiation: X-rays (such as Kα and Kβ lines) released by electron transitions in the inner layer of the target material. (2) Energy Conversion and Efficiency Only about 1% of the electron energy is converted into X-rays, and the remaining is dissipated in the form of heat, requiring forced cooling (such as a rotating anode design). 3. Classification and application scenarios of X-ray tubes (1) By generating electronic means Inflatable tube: an early type that relies on gas ionization to generate electrons, with low power and short lifespan (now obsolete). Vacuum tube: Modern mainstream, high vacuum environment improves electronic efficiency and stability. (2) By purpose In the medical field, diagnostic (such as dental and breast examinations) and therapeutic (such as radiotherapy) X-ray tube often use rotating anodes to increase power density. Industrial testing: non-destructive testing, material structure analysis, etc., with a focus on high penetration (hard X-rays). (3) According to the cooling method Fixed anode: simple structure, suitable for low-power scenarios. Rotating anode: The target surface rotates at high speed (up to 10000 revolutions per minute) to improve heat dissipation and support high-power output. 4. Performance characteristics and limitations of X-ray tubes (1) Advantages Low cost, small size, easy operation, suitable for routine medical and industrial testing. Flexible adjustment of target materials (such as tungsten, molybdenum, copper) to meet different energy requirements. (2) Limitations Poor brightness and collimation, large X-ray divergence angle, requiring additional collimators. The energy spectrum is continuous and contains characteristic lines, requiring filtering or monochromatization (such as using nickel filters to remove Kβ lines). 5. Comparison between X-ray tubes and synchrotron radiation sources (1) Brightness and flux X-ray tube: Low brightness, suitable for routine testing. Synchrotron radiation light source: with a brightness 106~1012times higher, suitable for cutting-edge research such as nanoimaging and protein crystallography. (2) Spectral characteristics X-ray tube: Discrete characteristic lines+continuous spectrum, energy range limited by acceleration voltage. Synchrotron radiation: wide continuous spectrum (from infrared to hard X-rays), precisely tunable. (3) Time characteristics X-ray tube: Continuous or microsecond level pulses (rotating target). Synchrotron radiation: Femtosecond level pulses, suitable for studying dynamic processes such as chemical reactions. 6. Technical parameters of X-ray tube (1) Optional target material types: Cu, Co, Fe, Cr, Mo, Ti, W, etc (2) Focus type: 0.2 × 12mm2 or 1 × 10mm2 or 0.4 × 14mm2 (fine focus) (3) Larger output power: 2.4kW or 2.7kW Overall, X-ray tube dominate in fields such as medical diagnosis and industrial testing due to their practicality and economy, but are limited by performance bottlenecks. For scenes that require high resolution and high brightness (such as cutting-edge scientific research), advanced technologies such as synchrotron radiation sources need to be relied upon. Future development directions include improving energy conversion efficiency, optimizing heat dissipation structures, and developing miniaturized X-ray sources.

X-ray tubes device used to generate X-rays, widely used in laboratory analytical instruments such as X-ray diffractometers, such as medical imaging, industrial testing, and scientific research. In the industrial field, they are used to detect defects inside materials, such as welds, cracks, etc. In scientific research, X-ray tubes are used to study the structure and properties of substances.

X-ray tubes specifically designed for analytical instruments: corrugated ceramic tubes, cermet tube , and glass tubes ,suitable for various models of XRD, XRF, crystal analyzers, and orientation instruments at home and abroad. X-ray tubes technical parameter: 1. Optional target material types: Cu, Co, Fe, Cr, Mo, Ti, W, etc 2. Focus type: 0.2 × 12mm² or 1 × 10mm² or 0.4 × 14mm² (fine focus)

X-ray tubes specifically designed for analytical instruments: 1. There are various types of target materials: different target materials can be selected according to different analysis needs, such as tungsten, copper, cobalt, iron, chromium, molybdenum, titanium, etc. These target materials can generate X-rays with different characteristics to adapt to the analysis of various substances. 2. Rich focus types: There are multiple focus types to choose from, such as fine focus, which can meet the testing requirements of different resolutions and accuracies. For example, fine focal points of 0.2 × 12mm ², 1 × 10mm ², or 0.4 × 14mm ² can help improve the accuracy and precision of analysis. 3. High output power: A high output power can ensure that the X-ray tube has sufficient energy to excite the sample during operation, thereby obtaining clear analysis results. The output power of some specialized X-ray tubes can reach 2.4kW or 2.7kW. 4. Special structural materials: corrugated ceramic tubes, metal ceramic tubes, glass tubes and other materials are used, which have good high temperature resistance, corrosion resistance and radiation resistance, ensuring stable operation of X-ray tubes in complex working environments. At the same time, these materials also help improve the heat dissipation performance of X-ray tubes and extend their service life. 5. Customized services: Customers can customize according to their specific needs, including the design, configuration, and anode materials of the radiation tube, to meet specific analysis requirements. 6. High reliability: The X-ray tubes used by Dandong Tongda Technology Co., Ltd. ensure a reliable supply of X-ray tubes, ensuring the continuous provision of high-quality X-ray tubes during the instrument's service life and reducing instrument downtime caused by tube failures. 7. Widely applicable: Suitable for various models of XRD (X-ray diffractometer), XRF (X-ray fluorescence spectrometer), crystal analyzer, orientation analyzer and other analytical instruments at home and abroad, as well as industrial fields such as non-destructive testing, inspection, measurement, etc. In summary, X-ray tubes specifically designed for analytical instruments have the characteristics of diverse target materials, rich focal points, high power, special structural materials, customizability, high reliability, and wide applications. These features enable them to meet the analysis needs of various complex substances and are widely used in scientific research, industry, and other fields.

Dandong Tongda Technology Co., Ltd. is a professional enterprise that produces X-ray products. Its main product is X-ray analysis instruments, and in 2013, it became the project undertaker for the National Major Scientific Instrument and Equipment Development Special X-ray Single Crystal Diffraction Instrument of the Ministry of Science and Technology of China. Our company adheres to the principles of customer first, product first, and service first, insists on people-oriented, and has a strong technology team. We are committed to providing users with the highest quality high-tech products with advanced technology, and providing strong support and services to users with efficient technical consulting and after-sales service institutions.

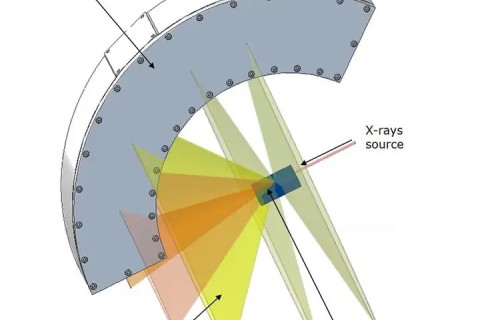

The TD series X-ray crystal analyzer is a large-scale analytical instrument used to study the internal microstructure of materials. It is mainly used for single product orientation, defect inspection, determination of lattice parameters, determination of residual stresses, study of the structure of plates and rods, and investigation of the structure of unknown substances and single crystal dislocations.

The high-precision multifunctional angle measuring instrument of Tongda Technology can not only measure conventional powder samples, but also test liquid samples, colloidal samples, viscous samples, loose powders, and large solid samples.

Recently, the Ministry of Science and Technology announced the list of the second batch of key projects under the 2023 National key research and Development Plan "Basic scientific research Conditions and major scientific instruments and equipment research and development".