NDT Portable X-ray Welding Testing Machine

1. The X-ray generator is small, the anode is grounded, and the fan is forced to cool.

2. Delay exposure to ensure operator safety;

3.Light weight, easy to carry, easy to operate;

4.Main uses: Check parts processing and welding quality, internal defects, etc.

- Tongda

- Liaoning, China

- 1—2 months

- 100 units per year

- Information

The main uses of NDT Portable X-ray Welding Testing Machine are:

NDT Portable X-ray Welding Testing Machine is suitable for the inspection of hull, pipeline, high pressure vessel, boiler, aircraft, vehicle and bridge materials and parts, welding quality and internal defects in national defense, shipbuilding, petroleum, chemical industry and other industrial departments.

Machinery, aerospace and construction. The inherent quality of all kinds of light metals, rubber, ceramics, etc.

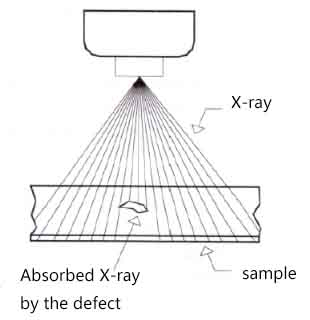

The principle and application of NDT Portable X-ray Welding Testing Machine:

Non-destructive testing is to make use of the sound, light, magnetic, electrical and other characteristics of the material to detect the defect or inhomogeneity of the tested object and the nature and quantity of information without damaging or affecting the performance of the tested object. Compared with destructive testing, Radiographic Inspection Equipment has the following characteristics. The first is non-destructive because it will not damage the performance of the tested object when being tested; the second is comprehensive, because the test is non-destructive, 100% full inspection of the object can be carried out if necessary.

This is impossible for destructive testing; third, full-size destructive testing is generally only suitable for testing raw materials, such as tension, compression, bending, etc., which is commonly used in mechanical engineering. Destructive testing is aimed at manufacturing raw materials, and for finished products and supplies, destructive testing can not be carried out unless they are not prepared to continue to serve, and non-destructive testing does not destroy the performance of the tested object.

Therefore, Radiographic Inspection Equipment can not only test the manufacturing raw materials, intermediate process links and the final finished products, but also inspect the equipment in service.

Visual range of NDT Portable X-ray Welding Testing Machine:

1. Inspection of weld surface defects.

Portable X-ray Machine for Weld Inspection can check the weld quality, such as weld surface crack, incomplete penetration, missed welding and so on.

2. Status check.

Portable X-ray Machine for Weld Inspection can check the surface for cracks, peeling, scratches, scratches, pits, bumps, spots, rust and other defects.

3. Intracavitary examination.

When some products (such as worm pump, engine, etc.) are working, endoscopic examination shall be carried out in accordance with the items specified in the technical requirements.

4. Assembly inspection.

When there are requirements and needs, use the same three-dimensional industrial video endoscope to check the assembly quality; after the assembly or a certain process is completed, check whether the assembly position of the zero components meets the requirements of drawings or technical conditions; whether there are assembly defects.

5. Inspection of surplus materials.

Radiographic Inspection Equipment can check whether the inner cavity of the product remains internal sundries, foreign bodies, etc.

About us :

Dandong Tongda Science & Technology Co.,Ltd. is located in China Dandong City City, Liaoning Province. The company is a national high-tech enterprise, a dual-soft enterprise in Liaoning Province, an ISO quality system certification enterprise, and has obtained a number of invention patents and utility model patents. It is a high-tech enterprise supported by the Liaoning Provincial Government and the Dandong Municipal Government, and in 2013, 5 On the 15th, an academician expert workstation was established. The company is a professional manufacturer of X-ray analytical instruments and non-destructive testing instruments. It is the project undertaker of the National Ministry of Science and Technology [National Major Scientific Instruments and Equipment Development Project] in 2013.