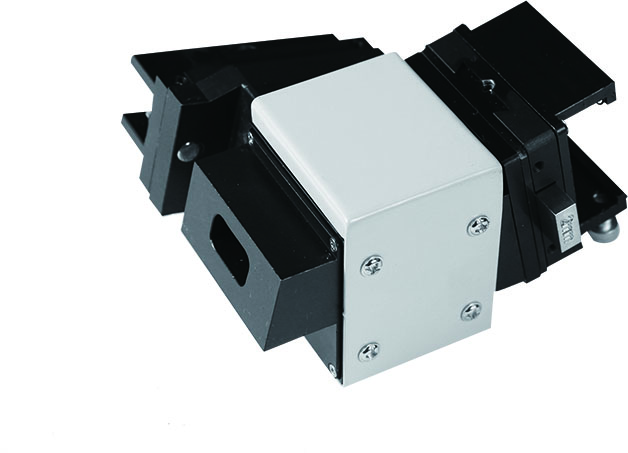

Graphite curved crystal monochromator

1.Name: Graphite curved crystal monochromator.

2.Application: Diffractometer accessories.

3.Function: increase the peak back ratio and weak peak resolution, reduce the diffraction Angle.

- Tongda

- Liaoning, China

- 1—2months

- 100 units per year

- Information

The graphite curved crystal monochromator is a critical component in X-ray diffraction analysis systems. It is typically installed in front of the detector to monochromatize the X-ray beam passing through the receiving slit, allowing only characteristic X-rays (such as the Kα line) to pass through. This design effectively eliminates interference from continuous X-rays, Kβ characteristic radiation, and fluorescent X-rays generated by the sample, thereby significantly enhancing analytical accuracy and reliability.

Core Technical Advantages

High Signal-to-Noise Ratio and Enhanced Resolution

The use of a graphite curved crystal monochromator significantly improves the peak-to-background ratio (the ratio of peak signal to background noise) and reduces the background of diffraction patterns. This feature is particularly beneficial for detecting weak diffraction peaks or faint signals hidden within strong backgrounds, improving the resolution of weak peaks and supporting fine structural analysis.

Reflection Efficiency and Diffraction Angle Optimization

The reflection efficiency (η) of the graphite curved crystal monochromator is typically no less than 35%. High reflection efficiency ensures minimal intensity loss of X-ray signals while appropriately reducing the measurement angle of the diffractometer, thereby enhancing the overall performance and usability of the equipment.

Key Performance Parameters

Crystal Type Selection: Depending on analytical requirements, either graphite curved crystals or flat crystals can be selected. The curved crystal structure helps focus X-rays, improving signal intensity, while flat crystals are more suitable for conventional monochromatization scenarios.

Mosaic Control: The mosaic degree of the crystal is typically required to be ≤0.55°. The mosaic degree reflects the directional consistency of the crystal lattice within the crystal. A lower mosaic degree indicates higher crystal integrity and monochromatization performance, contributing to sharper diffraction peaks.

Adjustment Flexibility: The crystal surface supports tilting adjustment of ±2°. This design allows fine-tuning of the monochromator to adapt to different optical path configurations and analytical conditions, ensuring X-rays incident at the optimal angle and maintaining high monochromatization efficiency.

Application Scenarios and Compatibility

The graphite curved crystal monochromator performs exceptionally well in various analytical scenarios:

Fluorescence Suppression: When used with copper target X-ray tubes, it effectively eliminates fluorescent radiation from samples containing elements such as manganese (Mn), iron (Fe), cobalt (Co), and nickel (Ni), making it suitable for diffraction analysis of samples with complex compositions.

Materials and Environmental Protection Fields: Widely used in phase analysis, crystallite size calculation, and crystal structure analysis in fields such as environmental monitoring and electronic materials. For example, in Dandong Tongda's TD-3500 X-ray diffractometer for phase analysis, the monochromator technology plays a key role in improving the accuracy of crystallinity calculations.

![]()

Graphite curved crystal monochromator(diffractometer accessories)