XRD inspection of wafers and epitaxial wafers

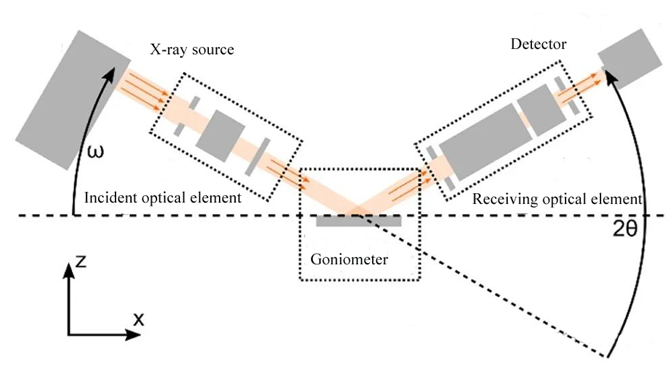

2024-05-15 23:00X-ray diffraction technique is often used to detect the crystal quality of wafers and epitaxial wafers. With this measurement technique, information such as phase and lattice constants, crystallinity, dislocation density, residual stress, and composition and thickness can be obtained. Figure 1 shows the schematic diagram of conventional XRD instruments.

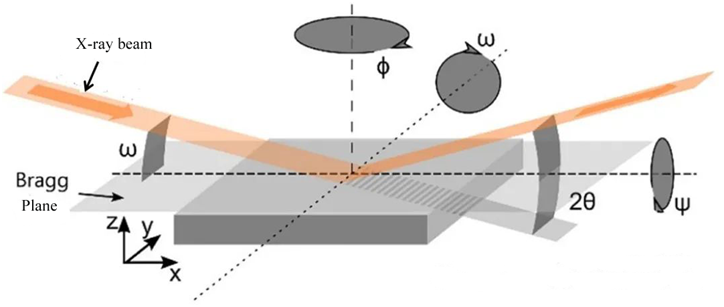

According to different scanning methods, Figure 2 shows the rotational degrees of freedom of the X-ray source, detector and sample. XRD detection has the following measurement methods:

(1) 2θ/θ scan, where θ is usually half of 2θ. It is also a commonly used scanning method for XRD measurement of powder samples, also known as symmetric or coupled scanning. For very thin film samples, the X-ray beam can be fixed at a small scanning Angle, and the detector moves in the direction of 2θ to collect signals. Such a small Angle detection method is also called grazing incidence XRD detection. The phase structure, stress strain and grain size of the sample can be obtained by the X-ray diffraction peaks scanned by 2θ/ω.

(2) Polar graph measurement. The polar diagram is circular and is usually made in polar coordinates with radial coordinates θ and angular coordinates θ. It is particularly suitable for surface texture samples. In some cases, a complete or series of polar images is not necessary and can be measured using an azimuth scan, θ scan. At this time, the out-of-plane orientation information needs to be determined in advance by 2θ/θ scanning, and the internal information of the crystal face can be obtained by pole image measurement or θ scanning, so as to further judge the symmetry of the crystal.