A classic case of in-situ XRD for all-solid-state batteries

2023-09-03 10:00In situ X-ray diffraction

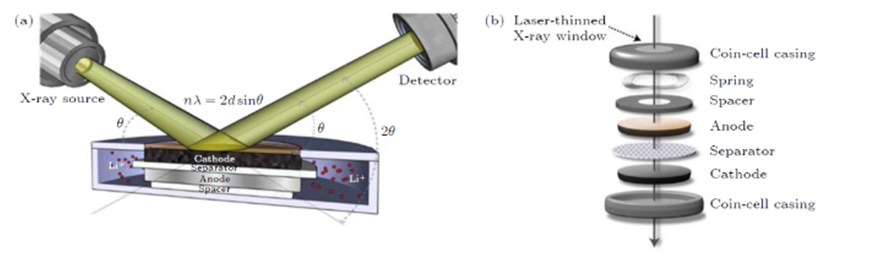

Based on Bragg's Law, in-situ X-ray diffraction (XRD) can be used to monitor the change of phase and its lattice parameters in the electrode or electrode-electrolyte interface in real time during the charge-discharge cycle of a battery. It provides important perspective and data support for further study of battery operation and failure mechanism.

Depending on the position of the X-ray signal collector relative to the incident X-ray source, there are two main designs of in situ XRD devices: reflective and transmitted.

Conventional laboratories typically use reflective devices (such as the one above (a)) where the incident X-rays are located on the same side of the battery as the signal collector, so the signal collected is mainly from the electrode surface exposed to the X-rays. Transmitted in situ XRD (as shown in Figure (b)) incident X-rays typically come from synchrotron radiation sources, have extremely high intensity, can directly penetrate the entire battery, and significantly improve the signal-to-noise ratio and signal acquisition speed. The electrochemical performance of all-solid state battery mainly depends on the performance of solid electrolyte and its interface with electrode, so the controllable synthesis and characterization of solid electrolyte is of great significance for the development of all-solid state battery.

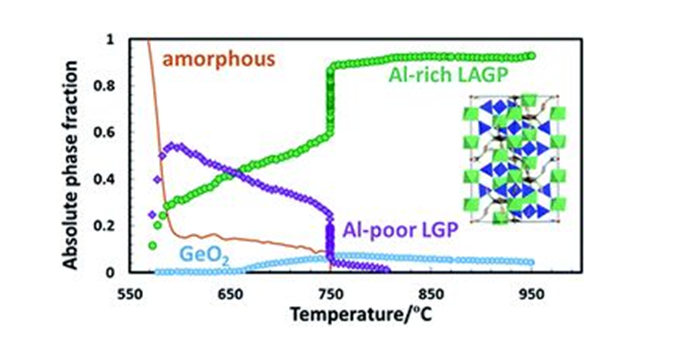

1. Stefan Adams' team at the National University of Singapore used synchrotron radiation in-situ XRD to real-time monitor the high-temperature synthesis process of LAGP, a typical NASICON solid electrolyte, and found that aluminum can be effectively incorporated into LGP only when sintered at 800 ℃ for a long enough time. Thus, a pure phase LAGP solid electrolyte with higher ionic conductivity is obtained, and higher temperature sintering (e.g. 950℃) causes the outer layer of LAGP particles to dealuminate and the appearance of non-pure phase.

Safanama D, Sharma N, Rao R P, et al. Structural evolution of NASICON-type Li 1+ x Al x Ge 2− x (PO 4) 3 using in situ synchrotron X-ray powder diffraction[J]. Journal of Materials Chemistry A, 2016, 4(20): 7718-7726.

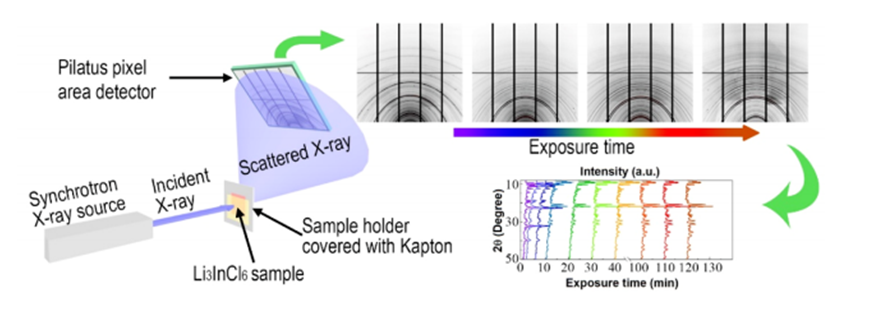

2. Sun Xueliang et al., University of Western Ontario, Canada, studied the stability of halide solid electrolyte Li3InCl6 in air by using synchrotron radiation in-situ XRD and in-situ X-ray near-side absorption structure (XANES), etc., and revealed the mechanism of its degradation of ionic conductivity due to water absorption.

Li W, Liang J, Li M, et al. Unraveling the origin of moisture stability of halide solid-state electrolytes by in situ and operando synchrotron X-ray analytical techniques[J]. Chemistry of Materials, 2020, 32(16): 7019-7027.

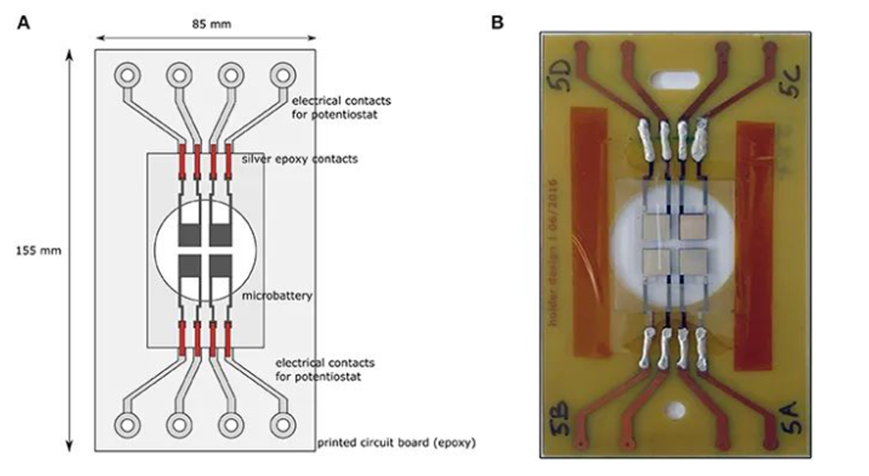

3. Negative electrode materials. Neeraj Sharma's team at the University of New South Wales in Australia used synchrotron radiation in-situ XRD to study the thin film half battery based on the solid electrolyte LiPON, and monitored the process of gradually transforming bismuth lithium into bismuth during charging in real time.

Goonetilleke D, Sharma N, Kimpton J, et al. Insight Into the Formation of Lithium Alloys in All-Solid-State Thin Film Lithium Batteries[J]. Frontiers in Energy Research, 2018, 6: 64.

In-situ XRD, especially in-situ transmission XRD based on synchrotron radiation source, is a non-contact, non-destructive real-time monitoring technology, mainly used to study the changes in the phase or crystal structure of solid-state battery electrodes or solid-state electrolytes under different charging and discharging states, as well as the changes resulting from the continuous charging and discharging cycle. The charging and discharging mechanism and failure mechanism of solid state battery can be deeply revealed.

However, due to the scarcity of synchrotron radiation resources, most in-situ XRD experiments can only be carried out by reflection scanning through conventional XRD equipment in the laboratory, which greatly reduces the amount and accuracy of information that can be obtained, and greatly prolongs the scanning time required, and requires fine design of in-situ batteries due to the limitations of conventional XRD detection depth.