- Home

- >

News

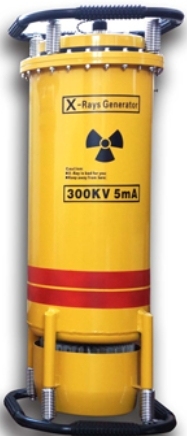

Non-Destructive Testing (NDT) is an indispensable quality assurance technology in modern industry. It enables the detection of internal defects, structures, and property conditions of materials by utilizing characteristics such as acoustic, optical, magnetic, and electrical properties—all without damaging or affecting the performance of the tested object. Compared to destructive testing, NDT has the following characteristics: First, it is non-destructive, as it does not impair the performance of the test object. Second, it is comprehensive. Since the testing is non-destructive, it allows for 100% full inspection of the test object when necessary, which is impossible with destructive testing. Third, it is full-process applicable. Destructive testing is generally only suitable for raw materials, such as tensile, compression, and bending tests commonly used in mechanical engineering. Destructive testing is conducted only on raw materials for manufacturing. For finished products and in-service equipment, destructive testing cannot be performed unless they are no longer intended for use. In contrast, NDT does not damage the test object’s performance, making it suitable for full-process testing, from raw materials and intermediate manufacturing stages to final products, as well as for in-service equipment. Among the many manufacturers of non-destructive testing equipment, Dandong Tongda Technology Co., Ltd. has developed a variety of NDT instruments that approach or achieve internationally advanced levels, thanks to its solid technical expertise and innovative capabilities. Technical Features: Portability, Safety, and Intelligence Tongda Technology's NDT Portable X-ray Welding Testing Machine exhibit several outstanding features. Their X-ray generators adopt an anode grounding and fan-forced cooling design, making them compact, lightweight, portable, and easy to operate. In terms of safety performance, the equipment is equipped with a delayed exposure function, effectively ensuring operator safety. The devices operate on a 1:1 work-rest cycle, with a rational duty cycle design that ensures detection efficiency while extending the equipment’s service life. The company’s products incorporate Programmable Logic Controller (PLC) technology and a modular design concept, enhancing automation, improving anti-interference capabilities, and ensuring an extremely low failure rate. Application Areas: Wide Adoption Across Multiple Industries Tongda Technology's NDT Portable X-ray Welding Testing Machine are suitable for various industrial sectors, including national defense, shipbuilding, petroleum, chemicals, machinery, aerospace, and construction. These instruments are used to inspect the welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges, as well as the internal quality of various lightweight metals, rubber, ceramics, and other materials.

The main purpose of NDT portable X-ray welding testing machine is to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges in industrial sectors such as national defense, shipbuilding, petroleum, chemical, mechanical, aerospace, and construction, as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc. The principle and application of NDT portable X-ray welding testing machine: NDT portable X-ray welding testing machine utilize the acoustic, optical, magnetic, and electrical properties of materials to detect the presence of defects or unevenness in the tested object without damaging or affecting its performance. They provide information such as defect size, location, nature, and quantity. Compared with destructive testing,it has the following characteristics. The first is non-destructive, as it does not compromise the performance of the detected object during testing; The second is comprehensive, as the detection is non-destructive, it is necessary to conduct a 100% comprehensive detection of the tested object, which cannot be achieved by destructive detection; The third is comprehensive, and destructive testing is generally only applicable to the testing of raw materials, such as tension, compression, bending, etc. commonly used in mechanical engineering. Destructive testing is carried out on manufacturing raw materials, and for finished products and in use items, destructive testing cannot be carried out unless they are not intended to continue to serve.on the other hand, it does not damage the performance of the tested object. So,it can not only perform full process testing on manufacturing raw materials, intermediate processes, and even final products, but also test equipment in service. Characteristics of NDT portable X-ray welding testing machine: The X-ray generator has a small volume, with an anode grounded and forced cooling by a fan; ◆ Lightweight, easy to carry, and simple to operate; Work and rest in a 1:1 ratio; Beautiful appearance and reasonable structure; ◆ Delayed exposure to ensure operator safety; Visual inspection range of NDT portable X-ray welding testing machine 1. Inspection of surface defects on welds. Check the welding quality such as surface cracks, incomplete penetration, and leakage of the weld seam. 2. Status check. Check for surface cracks, peeling, pulling, scratches, dents, protrusions, spots, corrosion, and other defects. 3. Internal cavity inspection. When certain products (such as worm gear pumps, engines, etc.) are working, perform endoscopic testing according to the specified technical requirements. 4. Assembly inspection. When there are requirements and needs, use the same 3D industrial video endoscope to inspect the assembly quality; After assembly or a certain process is completed, check each component.Whether the assembly position of the components meets the requirements of the drawings or technical specifications; Is there an assembly defect. 5. Excess item inspection. Check for residual debris, foreign objects, and other debris inside the product cavity.

The TDM-10 desktop x ray diffraction instrumentation is an instrument used for analyzing the phase structure of materials, which can be equipped with scintillation/proportional/linear array detectors. 1. The working principle of TDM-10 desktop x ray diffraction instrumentation:Based on Bragg's law, when a monochromatic X-ray beam is incident on a crystal, if the Bragg diffraction condition is satisfied (n λ=2dsin θ, where λ is the wavelength of the X-ray, d is the interplanar spacing, and θ is the incident angle), atoms or molecules in the crystal will scatter and interfere with the X-ray, forming a specific diffraction pattern. By measuring the diffraction intensity at different angles, the structural information of the crystal can be obtained. 2. Characteristics of TDM-10 desktop x ray diffraction instrumentation: The high resolution of a desktop x ray diffraction instrumentation enables precise measurement of the crystal structure of substances, which is crucial for studying complex mixtures or searching for low content polycrystalline and trace phases. Non destructive analysis of desktop x ray diffraction instrumentation: During the testing process, it will not cause damage to the sample, and the sample can remain in its original state for further testing or use. The operation of desktop X-ray powder diffraction equipment is simple: Modern desktop X-ray powder diffraction equipment usually have automation and intelligence functions, making the operation more convenient and reducing the requirements for the operator's professional knowledge and skills. The versatility of desktop X-ray powder diffraction equipment: X-ray powder diffraction equipment can perform various analyses such as phase qualitative and quantitative analysis, lattice constant analysis, stress analysis, etc. 3. Technical parameters of TDM-10 desktop X-ray powder diffraction equipment: Desktop x ray diffraction machine has a small volume; High frequency and high voltage power supply reduces the overall power consumption of the machine; Can quickly calibrate and test samples; Simple circuit control, easy to debug and install; The measurement accuracy of diffraction peak position is 0.001 °; Detector: scintillation, proportional, linear array; Range of 2 θ:- 10°~150° Power: 600W; Maximum voltage: 40kV; Maximum current: 15mA; X-ray tubes: corrugated ceramic tubes, metal ceramic tubes, glass tubes. 4. Application areas of TDM-10 desktop x ray diffraction machine: Materials Science: Used to study the crystal structure, phase composition, grain size, crystallinity, etc. of metals, ceramics, semiconductors, and other materials, helping materials scientists understand the properties and characteristics of materials. In the field of chemistry, x ray diffraction machine can be used in the manufacturing industry of catalysts, cement, pharmaceuticals, and other products to identify phases in unknown samples, as well as to quantitatively analyze known phases in mixed samples. Geology: Conducting phase analysis on ores, rocks, etc. to determine their mineral composition and structure. Environmental science: used to analyze the mineral composition and pollutant forms in environmental samples such as soil and sediment. Food industry: detecting crystal components, additives, etc. in food. The TDM-10 desktop x ray diffraction machine is a powerful analytical instrument with important application value in multiple fields.

The principle and application of NDT portable X-ray welding testing machine: NDT portable X-ray welding testing machine is the use of the acoustic, optical, magnetic, and electrical properties of materials to detect the presence of defects or unevenness in the tested object without damaging or affecting its performance. It provides information on the size, location, nature, and quantity of defects. Compared with destructive testing, non-destructive testing has the following characteristics. The first is non-destructive, as it does not compromise the performance of the detected object during testing; The second is comprehensive, as the detection is non-destructive, it is necessary to conduct a 100% comprehensive detection of the tested object, which cannot be achieved by destructive detection; The third is comprehensive, and destructive testing is generally only applicable to the testing of raw materials, such as tension, compression, bending, etc. commonly used in mechanical engineering. Destructive testing is carried out on manufacturing raw materials, and for finished products and in use items, destructive testing cannot be carried out unless they are not intended to continue to serve. Non destructive testing, on the other hand, does not damage the performance of the tested object. So, It can not only perform full process testing on manufacturing raw materials, intermediate processes, and even final products, but also test equipment in service. Characteristics of NDT portable X-ray welding testing machine: The X-ray generator has a small volume, with an anode grounded and forced cooling by a fan; ◆ Lightweight, easy to carry, and simple to operate; Work and rest in a 1:1 ratio; Beautiful appearance and reasonable structure; ◆ Delayed exposure to ensure operator safety; The main purpose of NDT portable X-ray welding testing machine : The main purpose of the equipment is to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges in industrial sectors such as national defense, shipbuilding, petroleum, chemical, mechanical, aerospace, and construction, as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc.

NDT portable X-ray welding testing machine is mainly suitable for industrial sectors such as national defense, shipbuilding, petroleum, chemical, mechanical, aerospace, and construction to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers, aircraft, vehicles, and bridges, as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc.

NDT portable X-ray welding testing machine is a type of radiographic inspection equipment that can generate X-rays and has multiple uses. Portable X-ray machine for weld inspection can be used in industrial and medical fields. In industry, it is used for defect detection in automotive parts manufacturing, wheel hub detection, subframe detection, hinge quality detection, etc., to ensure that the tested industrial products have high strength. In addition, its belongs to X-ray weld inspection equipment and is commonly used for weld detection, boiler weld detection, aerospace component weld detection, etc.

The NDT non-destructive testing instrument is a small X-ray generator with an anode grounded and forced cooling by a fan; Dandong Tongda Technology's customized wholesale non-destructive testing instruments are lightweight, easy to carry, and easy to operate; Portable welding seam X-ray machine non-destructive testing instrument works and rests in a 1:1 ratio; Radiographic testing equipment: aesthetically pleasing and structurally sound; NDT non-destructive testing instruments are: delayed exposure to ensure operator safety; The main purpose of NDT non-destructive testing equipment is to inspect the processing and welding quality of materials and components such as ship hulls, pipelines, high-pressure vessels, boilers,aircraft,vehicles, and bridges in industrial sectors such as national defense,shipbuilding, petroleum,chemical,mechanical,aerospace,and construction,as well as internal defects and the inherent quality of various light metals, rubber, ceramics, etc.

Today, let's share some knowledge of X-ray diffractometer operation, mainly in the following aspects.

It uses the X-ray principle to carry out qualitative or quantitative analysis and crystal structure analysis of polycrystalline materials such as powder samples and metal samples.